CC Aluminum Circle refers to aluminum circles produced through the Continuous Casting (CC) process.

Unlike DC aluminum circles, CC circles offer advantages such as ease of processing and lower cost.

Common Surface Treatments: CC aluminum circles can be surface treated as needed, such as anodizing, coating, etc., to enhance their corrosion resistance and decorative properties.

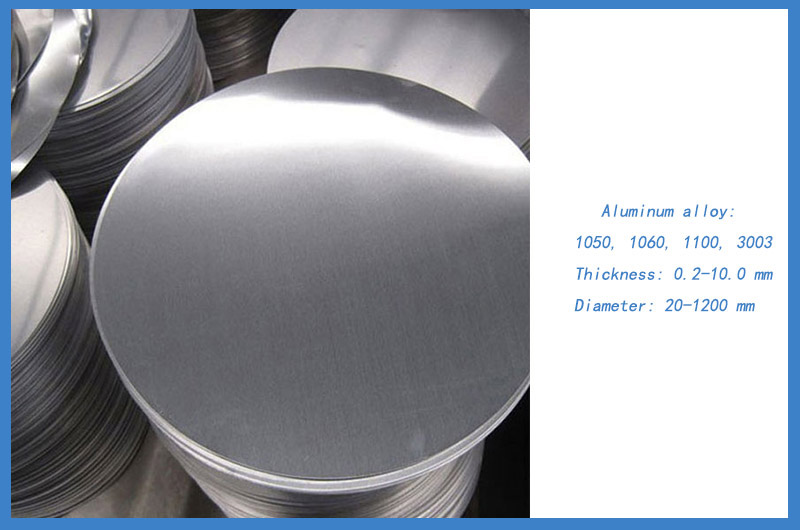

CC aluminum circles are versatile and high-performance aluminum products, widely used in applications requiring lightweight, corrosion resistance, and good formability.

Haomei Aluminum CC aluminum circles feature high strength, formability, and excellent corrosion resistance and can be further processed through deep drawing, spinning, and other methods.

The continuous casting (CC) process is an efficient and economical method for producing aluminum circles, particularly suitable for large-scale production.

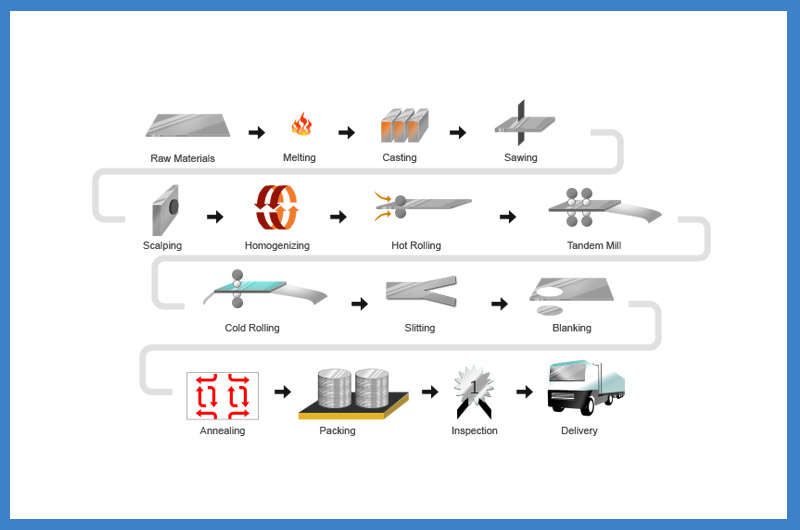

1. Aluminum Liquid Casting

Aluminum Liquid Preparation: The aluminum liquid typically consists of aluminum blocks or alloys melted in an aluminum smelting furnace, refined and filtered to remove impurities, ensuring the purity and quality of the liquid aluminum.

Casting System: The aluminum liquid flows into a mold through the nozzle of the casting machine. The mold usually consists of two cooled metal plates that hold the aluminum liquid during casting. The aluminum liquid solidifies in the mold to form a preliminary aluminum strip.

2. Cold Rolling or Hot Rolling Processing

Cold Rolling: The preliminary cast aluminum strip is processed through a cold rolling mill, where multiple rollers compress the strip, reducing its thickness and improving its surface finish. Cold rolling occurs at room temperature and can further refine the thickness and properties of the aluminum strip.

Hot Rolling (if required): If specific thermal treatment properties are needed for the aluminum circles, the preliminary cast aluminum strip may undergo hot rolling. Hot rolling occurs at high temperatures, which helps improve the plasticity and flowability of the aluminum material, achieving the desired thickness.

3. Quality Control and Post-Processing

Quality Inspection: During the continuous casting process, aluminum circles undergo a series of quality checks, including thickness measurement, surface defect detection, and strength testing, to ensure the products meet specification requirements.

Cutting and Coiling: After rolling, the aluminum strip is cut into the required circle sizes or coiled for subsequent processing and use.

Deep drawing performance of cast aluminum circles is generally poorer compared to hot-rolled aluminum circles and is rarely used for deep drawing. High-quality aluminum circles are typically hot-rolled products, with no color difference after anodizing and strong ductility, suitable for stretching, deep drawing, spinning, anodizing, and other subsequent processes.

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | V | Ti | Other | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.05 | 0.03 | 0.03 | 99.6 |

| 1100 | 0.95 | 0.95 | 0.05-0.2 | 0.05 | / | 0.1 | / | / | 0.05 | 99 |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | / | 0.1 | / | / | 0.15 | 96.95-96.75 |

Please feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.