5454 aluminum alloy is a high-strength, corrosion-resistant material primarily composed of aluminum and magnesium. It belongs to the 5000 series of aluminum alloys and is known for its excellent weldability and medium-to-high strength. This alloy is commonly used in applications requiring durability and resistance to harsh environments.

The most notable characteristics of 5454 aluminum include weldability, formability, corrosion resistance, and strength.

5454 rust-resistant aluminum has a strength approximately 20% higher than 5052, with properties similar to 5154 but better corrosion resistance in harsh environments. It is used in automotive wheels.

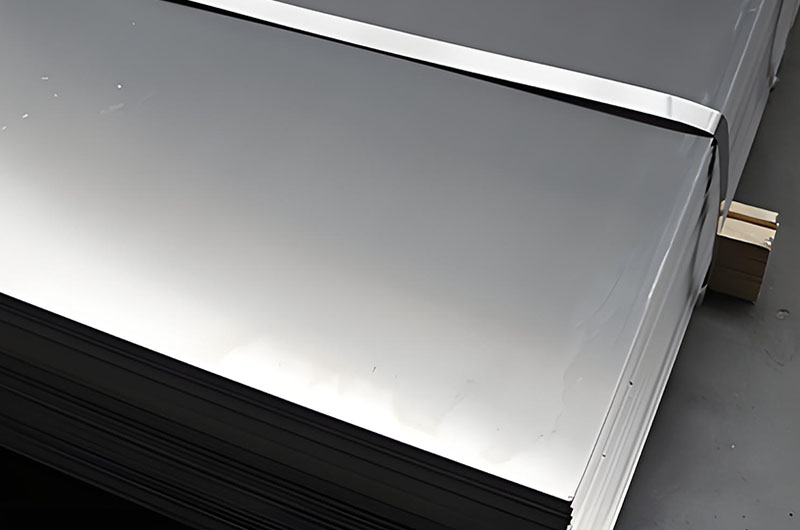

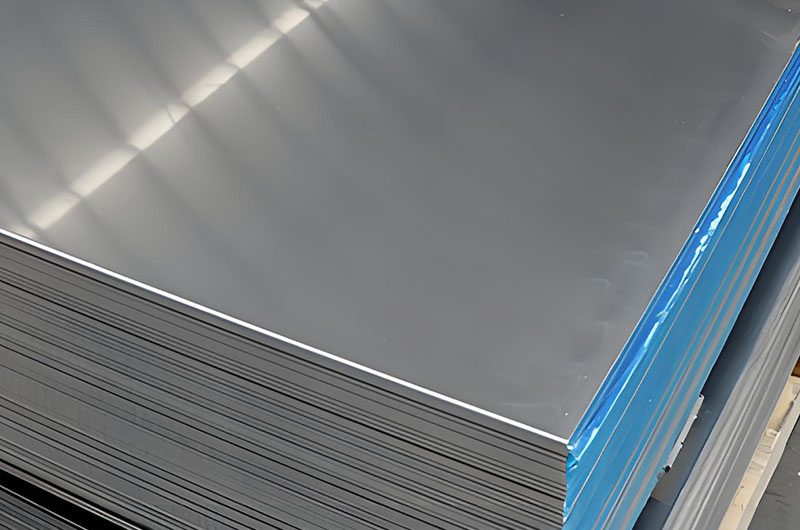

5454 aluminum plate is a versatile, medium-strength alloy optimized for environments that require corrosion resistance, weldability, and moderate mechanical stress. Its balanced properties make it a preferred choice in the marine, transportation, and industrial sectors.

At Haomei Aluminum, we are committed to providing high-quality aluminum products, especially our 5454 aluminum plate/sheet, which is widely used across multiple industries. Our 5454 aluminum plate has earned widespread acclaim in the market for its excellent corrosion resistance, strength, and good weldability. Through our advanced production facilities and stringent quality control systems, we ensure that each aluminum plate meets international standards, capable of meeting customer needs in extreme environments.

Our 5454 aluminum plate is especially suitable for marine, transportation, and chemical engineering applications. In marine environments, it can effectively extend the product's lifespan due to its excellent resistance to seawater corrosion. Whether processing, forming, or welding, it maintains good processing performance and stable quality.

With modern production lines and technical support, our products are sold worldwide, including to over 160 countries such as India, Tanzania, South Africa, Australia, and more, earning high recognition from global customers. We firmly believe that with our technical strength and product quality, Haomei Aluminum will continue to provide higher quality aluminum alloy materials for customers around the world.

| Item | Specification |

| Alloy Type | 5000 series (primarily aluminum and magnesium) |

| Temper | H32 (strain-hardened + stabilized), H34 (higher strain-hardened) |

| Ductility | Good (suitable for forming and processing) |

| Surface Treatment | Can be anodized, painted, suitable for protective coatings in harsh environments |

| Standards | ASTM B209, AMS 4025, EN 485 |

| Common Thickness Range | 1.0 mm ~ 100 mm (can be customized based on requirements) |

| Common Width Range | 1000 mm ~ 2500 mm (customizable) |

| Common Length Range | 2000 mm ~ 6000 mm (can be customized based on requirements) |

UNS A95454, ISO AlMg3Mn, Aluminium 5454, AA5454, Al5454

| Property | Aluminum 5454 Alloy |

| Principal Design Features | Non-heat treatable alloy of aluminum and magnesium. |

| Machinability | Fair to poor, machining recommended in H-34 temper with oil lubricants. |

| Forming | Good hot and cold working characteristics, readily cold worked in any temper. |

| Welding | All commercial methods work well, TIG or MIG with AL 5554 or 5356 filler rods recommended. |

| Heat Treatment | Not heat treatable, annealing for stress relief possible at 650°F. |

| Forging | Can be hot forged, consult supplier for temperature range. |

| Hot Working | Temperature range: 700 to 400°F. |

| Cold Working | Easily accomplished by conventional methods in annealed or temper conditions. |

| Annealing | Relieve cold working stress at 650°F, air cool after heating. |

| Aging | Not applicable. |

| Tempering | Not applicable. |

| Hardening | Hardens only by cold working. |

It has excellent resistance to saltwater, industrial chemicals, and atmospheric exposure. Compared to high-magnesium alloys such as 5083, it exhibits excellent stress corrosion cracking (SCC) resistance. It remains stable in marine environments and welded structures.

The most significant feature of 5454 aluminum plate is its exceptional corrosion resistance. It performs excellently in seawater environments, chemical media, and humid conditions. It is especially suitable for the marine and shipbuilding industries, where it can maintain high corrosion resistance even with prolonged exposure to seawater.

Compared to 5052 aluminum alloy, 5454 aluminum plate offers a 20% improvement in corrosion resistance, and its corrosion resistance is further enhanced compared to 5154 aluminum alloy, particularly in harsh marine environments.

| Chemical Element | Weight % |

| Manganese (Mn) | 0.50 - 1.00 |

| Iron (Fe) | 0.0 - 0.40 |

| Magnesium (Mg) | 2.40 - 3.00 |

| Silicon (Si) | 0.0 - 0.25 |

| Chromium (Cr) | 0.05 - 0.20 |

| Titanium (Ti) | 0.0 - 0.20 |

| Zinc (Zn) | 0.0 - 0.25 |

| Copper (Cu) | 0.0 - 0.10 |

| Other (Each) | 0.0 - 0.05 |

| Others (Total) | 0.0 - 0.15 |

| Aluminium (Al) | Balance |

| Material | Temper | Thickness (mm) | Tensile Strength (N/mm²) | Yield Strength (min) (N/mm²) | Elongation in 50mm (%) | ||||

| 0.5 mm | 0.8 mm | 1.3 mm | 2.6 mm | 3.0 mm | |||||

| Alloy 5454 Sheet | O | 0.2-6.0 | 215-285 | 80 | 12 | 14 | 16 | 18 | 14 |

| Alloy 5454 Sheet | H22 | 0.2-3.0 | 250-305 | 180 | 4 | 5 | 7 | 8 | - |

| Alloy 5454 Sheet | H24 | 0.2-3.0 | 270-325 | 200 | 3 | 4 | 5 | 6 | - |

| Physical Property | Value |

| Density | 2.69 g/cm³ |

| Melting Point | 645 °C |

| Thermal Expansion | 23.6 x10^-6 /K |

| Modulus of Elasticity | 70.5 GPa |

| Thermal Conductivity | 135 W/m.K |

| Electrical Resistivity | 34 % IACS |

5454 Aluminum Plate, due to its excellent corrosion resistance, high strength, good weldability, and adaptability, is widely used in marine, transportation, industrial, construction, automotive, and cryogenic systems. It is not only suitable for harsh environments but also has good low-temperature toughness and stress corrosion cracking resistance, making it a reliable material choice in multiple industries.

| Application Area | Description |

| Marine Applications: Shipbuilding and Offshore Structures | 5454 Aluminum Plate is highly suitable for marine environments due to its excellent corrosion resistance. It is widely used in shipbuilding, including for hulls, stairways, and offshore platforms. Its ability to resist seawater corrosion, especially with prolonged exposure to saltwater and humid environments, far exceeds that of other common aluminum alloys. In addition to ship structures, 5454 Aluminum Plate is also used in offshore oil rigs, floating structures, fishing vessels, and other critical marine equipment, ensuring their strength and structural integrity in harsh environments. |

| Transportation: Truck Trailers and Cryogenic Tanks | 5454 Aluminum Plate is widely used in the manufacturing of truck trailers and cryogenic tanks. Its high strength, corrosion resistance, and good weldability make it the preferred material in the transportation industry. Especially in vehicles that are exposed to harsh weather conditions for extended periods, 5454 Aluminum Plate provides a long service life. Moreover, its low-temperature toughness makes it ideal for cryogenic tank manufacturing, as it can withstand low-temperature stresses without becoming brittle. It is extensively used in the storage and transportation of low-temperature substances like liquefied natural gas (LNG) and liquefied petroleum gas (LPG). |

| Industrial: Pressure Vessels and Storage Tanks | 5454 Aluminum Plate is primarily used in the industrial sector for the production of pressure vessels, storage tanks, and chemical processing equipment. Due to its exceptional corrosion resistance, it can withstand exposure to various chemical media, particularly strong acids and alkalis. Additionally, its strength and weldability make it suitable for safety under internal and external pressures. Many chemical processing plants and petrochemical facilities use 5454 Aluminum Plate in the storage and transport of hazardous chemicals, reducing the risks of corrosion and leaks. |

| Construction: Corrosion-Resistant Structural Components | 5454 Aluminum Plate is commonly used in the construction industry to manufacture corrosion-resistant structural components. Due to its high corrosion resistance, it is especially suitable for marine environments, humid areas, and other harsh conditions. It is used in building facades, roof coverings, wall cladding, bridges, and other infrastructure, offering long-term structural stability and aesthetic appeal. Particularly in coastal cities, chemical plants, and other highly corrosive environments, 5454 Aluminum Plate is considered an ideal choice to significantly extend the lifespan of buildings. |

| Automotive and Transportation: Truck Bodies, Trailers, and Transport Vehicles | 5454 Aluminum Plate is widely used in the automotive and transportation sectors due to its high strength, excellent corrosion resistance, and good formability. It is particularly used in the manufacturing of truck bodies, trailers, and light transport vehicles, providing sturdy structural integrity while reducing vehicle weight, thereby improving fuel efficiency. The strength and durability of 5454 Aluminum Plate ensure that vehicles maintain good performance under heavy loads, while also resisting long-term exposure to weather changes, saltwater, and other corrosive substances. |

| Cryogenic Systems: Stress Corrosion Cracking Resistance | 5454 Aluminum Plate exhibits good resistance to stress corrosion cracking, making it indispensable in low-temperature applications. In cryogenic systems, material toughness and corrosion resistance are crucial, and 5454 Aluminum Plate effectively prevents stress corrosion cracking caused by temperature and pressure changes. It is widely used in liquid cooling systems, cryogenic storage equipment, and low-temperature component manufacturing in the aerospace sector, particularly in applications that involve the storage and transportation of liquids in low-temperature environments, such as liquefied gas transport and refrigerated warehouses. |

5454 Aluminum Plate Typical Applications

Popular application topics about 5454 aluminum plate

5454 Aluminum alloy is a versatile material combining strength, corrosion resistance, and weldability, suitable for demanding applications across various industries.

What are the characteristics of 5454 H32 aluminum compared to H34 aluminum?

5454 H32 aluminum and H34 have the same alloy composition and physical properties. But different tempering results in different mechanical properties. H34 undergoes further strain hardening, resulting in slightly higher tensile strength.

What is the density of 5454 aluminum?

5454 aluminum has a density of 168 lb/ft3, making it among the most dense 5000 series aluminum alloys.

Products you may be interested in

Please feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.