1235 aluminum foil is a foil product processed based on 1235 aluminum alloy, with an aluminum content of not less than 99.35%.

1235 aluminum foil is a high-purity aluminum product. This high purity endows the aluminum foil with various unique properties, making it highly attractive in a range of industrial and consumer applications.

1235 aluminum foil belongs to the 1xxx series commercial pure aluminum alloys. Due to its excellent formability, corrosion resistance, and lightweight characteristics, it is widely used. Because this alloy has comparable performance and higher availability, it is gradually replacing the older 1145 alloy in markets such as packaging and electronics.

The minimum aluminum content of 1235 aluminum alloy is 99.35%, making it the most common foil alloy on the market today. Its relatively high aluminum content makes it an excellent alloy for various industrial and food service markets. In the annealed state, it is very easy to process, form, and shape.

1235-O aluminum foil substrate is an ideal choice for sealing processing in various fields such as food, medicine, cosmetics, and wine sealing gaskets. It has a flat plate shape, clean surface, and no oil stains. It has high application value and broad prospects.

| Parameter | Specification Range/Description |

| Thickness | 0.0005 to 0.064 in |

| Width | 0.375 to 60 in (customization supported) |

| Alloy Temper | O, H12, H14, H18, etc. |

| Surface Quality | Free of roll marks, pinholes, oil stains, and other defects |

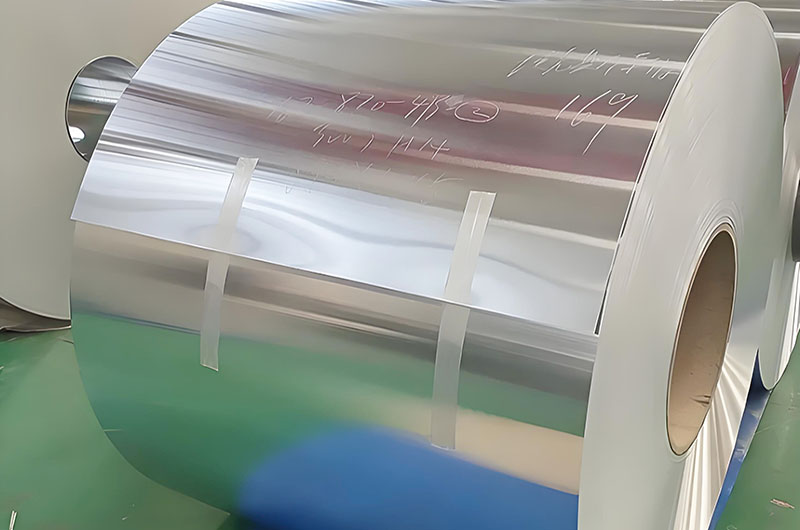

Haomei, as a highly specialized manufacturer of aluminum foil conversion base materials, has a strict quality control system and extensive industry experience. The company provides 1235 aluminum foil products that consistently meet performance specifications for packaging and household markets, whether in coil, sheet, or custom-cut pieces for flexible packaging, lids, household kitchen applications, or other uses.

| Elongation (Annealed): 1 | 35 |

| Elongation (H12): | 12 |

| Elongation (H14): | 9 |

| Elongation (H16): | 6 |

| Elongation (H18): | 5 |

| Tensile Strength (Annealed): 2 | 13 x 1000 psi |

| Tensile Strength (H12): | 16 x 1000 psi |

| Tensile Strength (H14): | 18 x 1000 psi |

| Tensile Strength (H16): | 21 x 1000 psi |

| Tensile Strength (H18): | 24 x 1000 psi |

| Yield Strength (Annealed): 3 | 5 x 1000 psi |

| Yield Strength (H12): | 15 x 1000 psi |

| Yield Strength (H14): | 17 x 1000 psi |

| Yield Strength (H16): | 20 x 1000 psi |

| Yield Strength (H18): | 22 x 1000 psi |

1 % in 2 inches

2 x 1000 psi

3 0.2% offset

| Property | Description |

| High-purity aluminum base material, excellent conductivity, uniform surface color, and cleanliness | 1235 aluminum foil is made from high-purity aluminum with an aluminum content typically above 99.35%, ensuring excellent electrical conductivity. This high-purity material exhibits superior conductivity in electronic and electrical applications, helping to improve current transmission efficiency. Additionally, 1235 aluminum foil undergoes a fine rolling process, giving it a uniform luster and clean surface appearance, meeting the stringent material appearance and safety requirements of the food and pharmaceutical packaging industries. |

| Good flexibility, high ductility, suitable for deep drawing and composite processing | 1235 aluminum foil has excellent flexibility and ductility, allowing deep drawing and forming into complex shapes without breaking. This property makes it particularly suitable for producing flexible packaging and composite materials, such as food soft packaging bags and pharmaceutical blister packs. Moreover, 1235 aluminum foil has good adhesion with other materials like plastic films or paper in composite processes, providing excellent sealing and protective performance for multi-layer packaging. |

| Outstanding rust resistance, formability, and weldability | 1235 aluminum foil offers excellent rust resistance, allowing it to withstand air and moisture corrosion while maintaining material integrity and aesthetics. This corrosion resistance ensures a long service life even in humid environments. Additionally, 1235 aluminum foil has excellent formability and weldability, facilitating mechanical or manual welding processes for fabrication and sealing. In the packaging industry, its welding sealability ensures the airtightness of packages, protecting contents from external contamination and oxidation. |

| Aluminum (Al): | 99.35% |

| Chromium (Cr): | - |

| Copper (Cu): | 0.05% |

| Iron (Fe): | - |

| Magnesium (Mg): | 0.05% |

| Manganese (Mn): | 0.05% |

| Other Total: | - |

| Silicon (Si): | 0.65% (Si+Fe) |

| Titanium (Ti): | 0.06% |

| Zinc (Zn): | 0.10% |

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | – | – | 0.05 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | – | – | 0.05 | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | – | – | 0.04 | 99.7 |

| 1100 | Si+Fe: 0.95 | 0.05-0.2 | 0.05 | – | – | 0.1 | – | 99 | |

| 1200 | Si+Fe: 1.00 | 0.05 | 0.05 | – | – | 0.1 | 0.05 | 99 | |

| 1235 | Si+Fe: 0.65 | 0.05 | 0.05 | 0.05 | – | 0.1 | 0.06 | 99.35 | |

| Product Type | Alloy Temper | Thickness(mm) | Tensile Strength(Mpa) | Elongation(%)A100mm |

| Food and Household Foil | 1235 O | 0.01-0.024 | 40-100 | ≥1 |

| 0.025-0.04 | 45-100 | ≥2 | ||

| 0.041-0.07 | 45-100 | ≥4 | ||

| 1235 H18 | 0.01-0.07 | ≥135 | – | |

| aluminium foil for capacitor | 1235 H18 | 0.02-0.05 | ≥135 | – |

| aluminium foil for cable | 1235 O | 0.01-0.024 | 40-100 | ≥1 |

| 0.025-0.04 | 45-100 | ≥2 | ||

| 0.041-0.07 | 45-100 | ≥4 | ||

| aluminium foil for adhesive tape | 1235 O | 0.012-0.04 | 50-90 | ≥1 |

| 1235 H18 | ≥135 | – | ||

| 1235 O | 0.03-0.07 | 60-100 | ≥2 |

| Application Field | Specific Uses | Description |

| Food and Beverage Packaging | Food Packaging, Beverage Packaging, Flexible Packaging | 1235 aluminum foil, with its excellent moisture resistance and odor protection properties, is widely used in food and beverage packaging. It effectively blocks air, light, and moisture, maintaining the freshness and flavor of food. It is commonly used in flexible packaging bags, chocolate packaging, dairy product seals, instant meal box liners, and coffee and tea packaging. Additionally, its non-toxicity and recyclability meet the environmental requirements of food packaging. |

| Pharmaceutical Packaging | Blister Packaging, Tablet Protective Lining | In the pharmaceutical field, 1235 aluminum foil is primarily used for blister packaging and tablet protective lining. It has excellent barrier properties that protect medications from moisture, oxygen, and light, ensuring the stability of drug efficacy. Pharmaceutical foil is often laminated with PVC or PVDC materials to create sealed packaging, making it convenient for long-term storage and transportation. Moreover, 1235 aluminum foil offers easy tearability, making it convenient for patients to access medications. |

| Electronic Applications | Lithium-ion Battery Cathode, Capacitor Foil, Cable Shielding Material | 1235 aluminum foil is used in the electronics industry for lithium-ion battery cathodes, capacitor foil, and cable shielding materials. As a current collector in lithium batteries, 1235 aluminum foil has excellent conductivity and chemical stability, ensuring efficient energy transfer. For capacitors, its thin and uniform structure makes it a critical component for energy storage. Additionally, in cable shielding, 1235 aluminum foil effectively prevents electromagnetic interference, ensuring stable signal transmission. |

| Industrial Applications | Insulation Material, Reflective Material, Aluminum Foil Tape | 1235 aluminum foil is widely used in industrial applications as insulation material, reflective material, and tape backing. Its high reflectivity and corrosion resistance make it an ideal choice for building insulation layers and HVAC (Heating, Ventilation, and Air Conditioning) systems. In reflective applications, 1235 aluminum foil is used in solar reflectors and lighting equipment to improve energy efficiency. Additionally, aluminum foil tape, known for its weather resistance and adhesion, is commonly used for sealing air conditioning ducts, cable wrapping, and equipment repairs. |

| Household Applications | Food Wrap, Baking Trays, BBQ Foil, Disposable Tableware | 1235 aluminum foil is an essential material in daily life, commonly used for food wrap, baking trays, BBQ foil, and disposable tableware. Its excellent thermal conductivity ensures even heating of food, while its oil resistance and anti-fouling properties make cleaning easier. Furthermore, its flexibility and high-temperature resistance make it ideal for baking and grilling applications. |

| Special Applications | Geochemical Sample Protection, Artistic Decoration, Cigarette Packaging | 1235 aluminum foil also has unique applications in specialized fields, such as geochemical sample protection, art and decoration, and cigarette packaging. In geochemical research, it is used as a sealing material to prevent sample contamination during transportation and storage. In the art and decoration sector, its metallic luster and flexibility make it suitable for creating metallic-looking decorative items and creative designs. In the tobacco industry, 1235 aluminum foil serves as a cigarette inner lining, maintaining the freshness of cigarettes while enhancing the packaging's premium appearance. |

Food Packaging

Industrial Applications

| Category | Temper | Thickness (mm) | Application |

| Aluminum Foil Tape | O | 0.015-0.03 | Made from 1235 aluminum foil as the base material, processed with lamination, printing, and adhesive coating; it features good thermal insulation, strong adhesion, and aging resistance. |

| Cable | O | 0.015-0.05 | Used as an insulation layer in cables, offering good conductivity, insulation, and corrosion resistance. |

| Lithium-Ion Battery | H14 | 0.012-0.02 | Used as a separator material in the production of lithium-ion batteries. |

| Insulation | O | 0.015-0.02 | The high reflectivity and thermal conductivity of 1235 aluminum foil make it an excellent choice for insulation, especially in the construction industry. |

| Electrical Applications | H14 | 0.015-0.05 | Due to its good conductivity, it can be used to produce capacitors, cables, and other electrical components. |

| Heat Exchanger | O | 0.015-0.05 | Used in heat exchangers due to its thermal conductivity and corrosion resistance. |

| Flexible Packaging | O | 0.012-0.02 | Used in the food and pharmaceutical industries for items like pouches and blister packs. |

| Cigarette Packaging | O | 0.006-0.007 | Commonly used as a lining for cigarette packaging to protect the product from moisture and oxygen. |

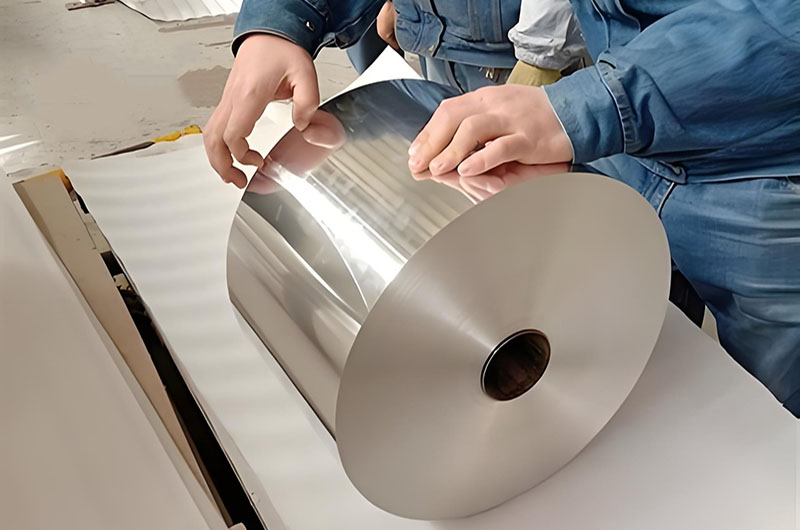

1235 aluminum foil is typically produced by casting high-purity aluminum and then undergoing a series of rolling processes. These processes reduce the material's thickness to extremely fine specifications — ranging from approximately 0.016 to 0.2 mm (even thinner for specific applications) — while ensuring a smooth, uniform surface and precise dimensional tolerances.

| Feature | 1235 Aluminum Foil | 8011 Aluminum Foil |

| Chemical Composition | Mainly contains 99.35% aluminum with almost no other alloy elements | Contains manganese (Mn) and magnesium (Mg) elements to enhance strength and corrosion resistance |

| Process | Lower annealing temperature, similar annealing time to 8011 aluminum foil | Higher annealing temperature with higher tensile strength |

| Tensile Strength | Lower | Higher |

| Elongation | Relatively high | Similar to 1235 aluminum foil |

| Applications | Mainly used for flexible packaging, such as milk packaging, cigarette packaging, beverage packaging, food packaging bags, etc. Commonly used in snack bags, cigarette packaging, chocolate packaging, etc. | Widely used in food containers, food packaging, pharmaceutical packaging, industrial applications, etc. Commonly found in household use, pharmaceutical packaging (with good moisture-proof, light-blocking, and barrier properties), and industrial uses (waterproof materials, air conditioning foil, cable foil, ventilation ducts, insulation materials, etc.) |

| Characteristics | Very thin (0.006mm-0.009mm), suitable for applications requiring flexibility | Suitable for various applications, environmentally friendly and recyclable, with a wide thickness range (up to 0.2mm, minimum thickness of 0.006mm), with higher strength and corrosion resistance |

Due to its comparable chemical composition and physical properties, manufacturers often use 1235 aluminum foil as a substitute for similar alloys like 1145.

With its high aluminum content (99.35%), exceptional ductility, excellent barrier properties, and outstanding thermal and electrical conductivity, 1235 aluminum foil is a versatile material used in various applications, from everyday household use to specialized industrial and pharmaceutical applications. Its production process ensures strict control over thickness and surface quality, enhancing its reliability and effectiveness as a material choice.

How to Choose Between 1235 and 8011 Aluminum Foil?

| Attribute/Aspect | 1235 Aluminum Foil | 8011 Aluminum Foil |

| Alloy Composition | Pure aluminum foil (Al content not less than 99.35%) | Aluminum with iron and silicon as major alloy elements |

| Main Use | Packaging material (such as food, medicine, cigarettes, etc.) | Packaging material and industrial applications (such as food packaging, industrial foils, insulation materials, etc.) |

| Strength | Lower compared to 8011 | Higher strength |

| Corrosion Resistance | Lower compared to 8011 | Better corrosion resistance |

| Cost | Lower cost | Higher cost due to alloying elements |

Users viewing this material also viewed the following

Please feel free to write down your requirement in the form below. We will reply you within 24 hours and we will protect your personal privacy information.