1050 Aluminum Plate Sheet

1050 aluminum plate belongs to the 1xxx series commercial pure aluminum alloy. Its characteristic is that the aluminum content is at least 99.5%, making it an ideal material for applications requiring excellent corrosion resistance, high electrical conductivity, and high ductility. However, due to its purity, its strength is only moderate compared to alloy grades.

1050 aluminum plate is a high-purity aluminum alloy known for its outstanding corrosion resistance, high thermal and electrical conductivity, and good workability. Due to these properties, it is commonly used in applications requiring high purity and excellent corrosion resistance.

1050 aluminum plate is one of the products in the pure aluminum plate series. Its chemical composition and mechanical properties are similar to those of the 1060 series. The 1050 alloy is well known for its excellent corrosion resistance, high ductility, and high reflectivity.

As a wrought alloy, 1050 aluminum is not used for casting. Instead, it is typically formed through extrusion or rolling. The production process of 1050 aluminum is relatively simple, and its cost is relatively low, making it one of the most commonly used series in conventional industries.

1050 aluminum is widely used in applications requiring moderate strength and formability, such as chemical equipment, construction components, and electrical conductors. This alloy cannot be heat-treated, but it can be strengthened through cold working.

1050 Aluminum Plate Standards and Designations

International: EN 485, ASTM B209

Other names: AA1050A, Al99.5, A91050, UNS A91050, Aluminium 1050, AA1050, Al1050

1050 Aluminum Plate Temper

Specifications of aluminium sheet alloy 1050

| Alloy | 1050 |

| Temper | O, H14 |

| Thickness | 0.2-260mm |

| Width | 500-2650mm |

| Hot Selling Sizes | 1250x2500, 1500x3000, 1520x3020, 1525x3660 |

Advantages of 1050 Aluminum Plate

| Feature | Description |

| Cost-Effective | 1050 aluminum plate is highly cost-effective, with low manufacturing costs and excellent processing performance, allowing for easy forming through both cold and hot working methods. This aluminum plate is suitable for applications requiring high conductivity and thermal conductivity, such as electrical equipment, heat exchange systems, and reflective materials. Its relatively low price and widespread use across multiple industries make it an extremely cost-efficient material choice. |

| High Recyclability | 1050 aluminum plate has extremely high recyclability. Since its chemical composition consists primarily of high-purity aluminum (99.5% aluminum content), the recycling process is simple, allowing for multiple regenerations while maintaining high quality. This property makes it an environmentally friendly material, particularly suitable for industries with high sustainability requirements, such as green buildings, environmental equipment manufacturing, and various aluminum products in the circular economy system. |

| High Anodizing Quality and Reflectivity | 1050 aluminum plate exhibits high anodizing quality and reflectivity. After undergoing anodizing treatment, the surface can form a uniform and dense oxide layer, enhancing both corrosion resistance and aesthetics while improving surface hardness. Additionally, its high reflectivity makes it widely used in the lighting industry, such as in lamp reflectors, solar reflectors, and optical equipment reflectors, effectively increasing light efficiency and reducing energy consumption. |

| Suitable for Lightweight and Corrosion-Resistant Designs | 1050 aluminum plate is well-suited for lightweight and corrosion-resistant designs. With a relatively low density of approximately 2.71 g/cm³ and excellent oxidation and corrosion resistance, it is widely used in lightweight yet durable structural components. For example, in the food, chemical, and medical equipment industries, 1050 aluminum plate is commonly used for manufacturing storage tanks, pipelines, and food processing equipment to ensure material durability and safety while reducing transportation and installation costs. |

1050 Aluminum Plate Fabrication

- Machinability: This alloy has excellent cold workability and is easy to roll, bend, and form into complex shapes.

- Machinability: Its high ductility results in relatively poor machinability.

- Weldability: It welds well through gas welding, arc welding, or resistance welding. When welding itself or similar alloys, filler 1100 is recommended. For different alloys such as 5083, 5086, or the 7XXX series, filler 5356 or 4043 is typically used.

- Tempering: The most common temper is H14 (work-hardened to a semi-hard state through rolling without subsequent annealing), though other tempers such as H18 can be used for specific applications.

Welding:

- Use filler 1100 for welding similar alloys.

- Use filler 5356 for 5xxx/7xxx series alloys.

- Use filler 4043 for other alloys.

- Brazing/Welding: Excellent.

Its simple production process and excellent formability make 1050 aluminum plate a cost-effective solution across a wide range of industries.

- Cold workability: Excellent, suitable for deep drawing, spinning, and bending.

- Mechanical machinability: Poor due to softness, but can be improved through cold working.

| Process | Rating |

| Workability - Cold | Excellent |

| Machinability | Poor |

| Weldability - Gas | Excellent |

| Weldability - Arc | Excellent |

| Weldability - Resistance | Excellent |

| Brazability | Excellent |

| Solderability | Excellent |

1050 Aluminum Plate Features

- High Purity: 1050 aluminum contains 99.5% aluminum, making it one of the purest forms of aluminum available.

- Corrosion Resistance: This alloy has excellent corrosion resistance, making it ideal for use in harsh environments, particularly in marine and chemical industries.

- Formability: 1050 aluminum is easy to manufacture, weld, and process, suitable for various manufacturing processes such as extrusion, forming, and stamping.

- Thermal and Electrical Conductivity: It has good thermal and electrical conductivity, suitable for applications such as conductors and heat exchangers.

- Not Heat Treatable: 1050 aluminum cannot be heat-treated to increase strength but can be hardened through work hardening processes.

- Strength: 1050 aluminum has moderate tensile strength, lower than alloys like 7075 or 2024, but still sufficient for many applications.

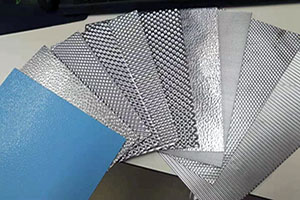

Haomei 1050 Aluminum Plate Sheet Popular Products

| Type of Aluminum Sheet | Image | Description |

| 1050 Color Coated Aluminum Sheet |

|

The 1050 color coated aluminum sheet is used for exterior building facades, signage, and interior decorative elements. |

| 1050 Aluminum Mirror Sheet |

|

The 1050 aluminum mirror sheet is used in decorative applications, lighting fixtures, and as a reflective surface. |

| 1050 Aluminum Tread Checkered Plate |

|

The 1050 aluminum tread checkered plate is used in flooring, stair treads, and as a protective covering for surfaces. |

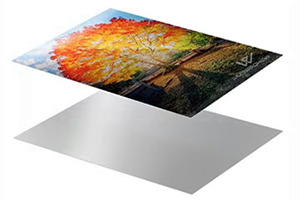

| 1050 Sublimation Aluminum Sheet |

|

The 1050 sublimation aluminum sheet is used in customized signage, photo panels, and other printed decorative elements. |

Haomei 1050 Aluminum Plate Sheet Inventory

1050 H24 Aluminum Plate Sheet Inventory

| Size & Description | Thickness/in | Applications |

| 1050 H24 0.008" Aluminum Sheet | 0.008" | Thin-wall containers, packaging materials, cable |

| 1050 H24 0.012" Aluminum Sheet | 0.012" | Thin-wall containers, packaging materials, cable |

| 1050 H24 0.016" Aluminum Sheet | 0.016" | Thin-wall containers, packaging materials, cable |

| 1050 H24 0.020" Aluminum Sheet | 0.020" | Electrical enclosures, kitchenware, decorative materials |

| 1050 H24 0.031" Aluminum Sheet | 0.031" | Electrical enclosures, kitchenware, decorative materials |

| 1050 H24 0.036" Aluminum Sheet | 0.036" | Electrical enclosures, kitchenware, decorative materials |

| 1050 H24 0.039" Aluminum Sheet | 0.039" | Electrical enclosures, kitchenware, decorative materials |

| 1050 H24 0.048" Aluminum Sheet | 0.048" | Automotive body panels, decorative panels, architectural cladding |

| 1050 H24 0.059" Aluminum Sheet | 0.059" | Automotive body panels, decorative panels, architectural cladding |

| 1050 H24 0.064" Aluminum Sheet | 0.064" | Automotive body panels, decorative panels, architectural cladding |

| 1050 H24 0.079" Aluminum Sheet | 0.079" | Automotive body panels, decorative panels, architectural cladding |

| 1050 H24 0.080" Aluminum Sheet | 0.080" | Automotive body panels, decorative panels, architectural cladding |

| 1050 H24 0.098" Aluminum Sheet | 0.098" | Automotive body panels, decorative panels, architectural cladding |

| 1050 H24 0.118" Aluminum Sheet | 0.118" | Aircraft structures, shipbuilding materials, pressure vessels |

| 1050 H24 0.157" Aluminum Sheet | 0.157" | Aircraft structures, shipbuilding materials, pressure vessels |

| 1050 H24 0.197" Aluminum Sheet | 0.197" | Aircraft structures, shipbuilding materials, pressure vessels |

| 1050 H24 0.236" Aluminum Sheet | 0.236" | Heavy machinery, structural construction |

| 1050 H24 0.315" Aluminum Plate | 0.315" | Heavy machinery, structural construction |

| 1050 H24 0.394" Aluminum Plate | 0.394" | Heavy machinery, structural construction |

| 1050 H24 0.472" Aluminum Plate | 0.472" | Heavy machinery, structural construction |

| 1050 H24 0.591" Aluminum Plate | 0.591" | Heavy machinery, structural construction |

| 1050 H24 0.787" Aluminum Plate | 0.787" | Heavy machinery, structural construction |

| 1050 H24 0.984" Aluminum Plate | 0.984" | Heavy machinery, structural construction |

Equivalent to 1050 Aluminum

Aluminium alloy 1050 also corresponds to: AA1050A, S1B and A91050, UNS A91050, Aluminium 1050, AA1050, Al1050

HC Provides 1050 Aluminum Products and Surface Finishes

| Product | Product Image | Description |

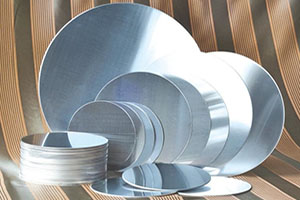

| 1050 Aluminum Disc |

|

The 1050 aluminum disc has excellent formability and corrosion resistance, making it suitable for various manufacturing and decorative applications. |

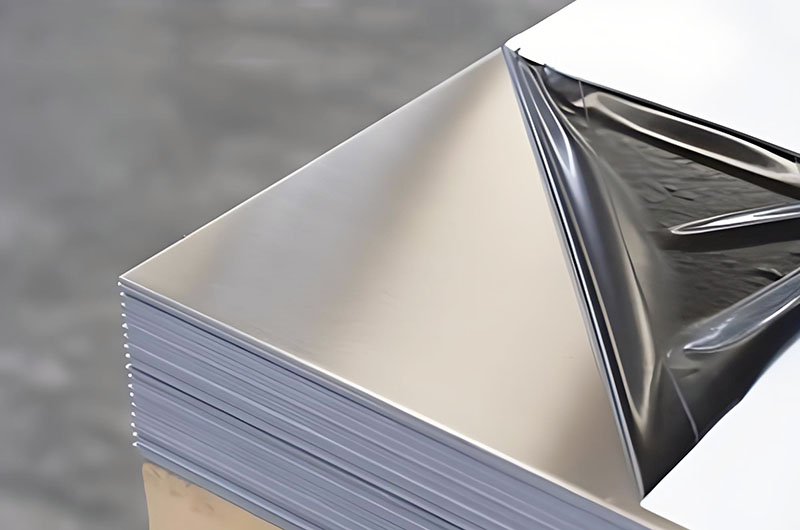

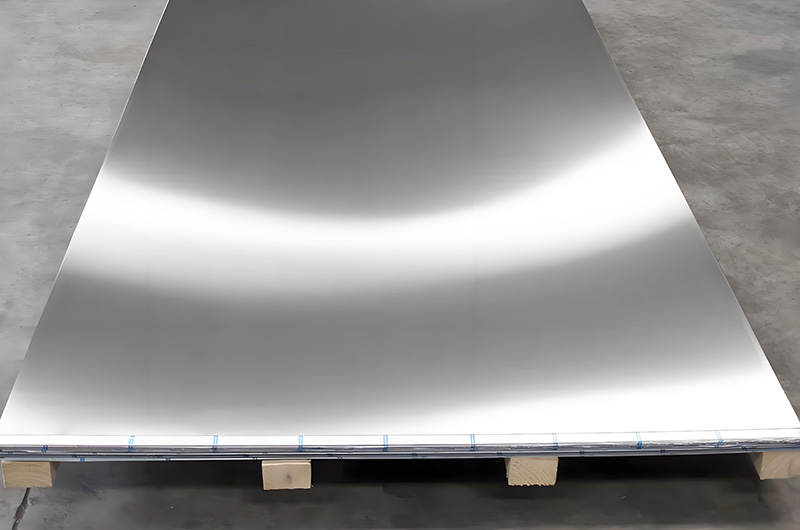

| 1050 Plain Aluminum Sheets |

|

1050 aluminum sheets are widely used in industrial fields due to their excellent weldability and good machinability. |

| 1050 Embossed Aluminum Plate |

|

The 1050 embossed aluminum plate provides better slip resistance and aesthetic appeal through its unique texture design, commonly used for decorative and anti-slip purposes. |

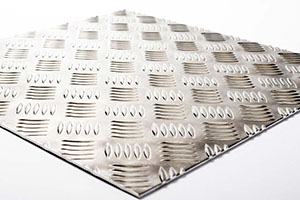

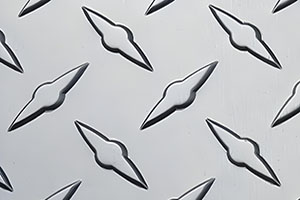

| 1050 Aluminum Diamond Plate |

|

The 1050 aluminum diamond plate has anti-slip properties and is widely used on floors and the surfaces of vehicles. |

| Orange Peel 1050 Aluminum Plate |

|

The 1050 orange peel aluminum plate has a texture similar to orange peel on the surface, creating a unique visual effect, suitable for decorative applications and high-end products. |

1050 Aluminum Plate Chemical Composition

| Element | % Present |

| Manganese (Mn) | 0.0 - 0.05 |

| Iron (Fe) | 0.0 - 0.40 |

| Copper (Cu) | 0.0 - 0.05 |

| Magnesium (Mg) | 0.0 - 0.05 |

| Silicon (Si) | 0.0 - 0.25 |

| Zinc (Zn) | 0.0 - 0.07 |

| Titanium (Ti) | 0.0 - 0.05 |

| Aluminium (Al) | Balance |

Mechanical Properties of 1050 Aluminum Sheet

| Alloy Temper | Specified | Tensile strength | Yield strength | Elongation |

| Thickness(mm) | (MPa) | (MPa) | (%) | |

| 1050-O/ 1050-H111 | 0.2-0.5 | 65-95 | Min20 | Min20 |

| 0.5-1.5 | Min22 | |||

| 1.5-3.0 | Min26 | |||

| 3.0-6.0 | Min29 | |||

| 6.0-12.5 | Min35 | |||

| 12.5-80.0 | ||||

| 1050-H112 | 6.0-12.5 | Min75 | Min30 | Min20 |

| 12.5-80.0 | Min70 | Min25 | ||

| 1050-H12 | 0.2-0.5 | 85-125 | Min65 | Min2 |

| 0.5-1.5 | Min4 | |||

| 1.5-3.0 | Min5 | |||

| 3.0-6.0 | Min7 | |||

| 6.0-12.5 | Min9 | |||

| 12.5-40.0 | ||||

| 1050-H14 | 0.2-1.5 | 105-145 | Min85 | Min2 |

| 1.5-3.0 | Min4 | |||

| 3.0-6.0 | Min5 | |||

| 6.0-12.5 | Min6 | |||

| 12.5-25 | ||||

| 1050-H16 | 0.2-0.5 | 120-160 | Min100 | Min1 |

| 0.5-1.5 | Min2 | |||

| 1.5-4.0 | Min3 | |||

| 1050-H18 | 0.2-0.5 | Min135 | Min120 | Min1 |

| 0.5-1.5 | Min140 | Min2 | ||

| 1.5-3.0 | Min2 | |||

| 1050-H19 | 0.2-0.5 | Min155 | Min140 | Min1 |

| 0.5-1.5 | Min150 | Min130 | ||

| 1.5-3.0 | ||||

| 1050-H22 | 0.2-0.5 | 85-125 | Min55 | Min4 |

| 0.5-1.5 | Min5 | |||

| 1.5-3.0 | Min6 | |||

| 3.0-6.0 | Min11 | |||

| 6.0-12.5 | Min12 | |||

| 1050-H24 | 0.2-0.5 | 105-145 | Min75 | Min3 |

| 0.5-1.5 | Min4 | |||

| 1.5-3.0 | Min5 | |||

| 3.0-6.0 | Min8 | |||

| 6.0-12.5 | ||||

| 1050-H26 | 0.2-0.5 | 120-160 | Min90 | Min2 |

| 0.5-1.5 | Min3 | |||

| 1.5-4.0 | Min4 | |||

| 1050-H28 | 0.2-0.5 | Min140 | Min110 | Min2 |

| 0.5-1.5 | ||||

| 1.5-3.0 | Min3 |

1050 Aluminum Plate General Physical Properties

| Physical Property | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 24 x 10-6/K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 222 W/m.K |

| Electrical Resistivity | 0.0282 x 10-6 Ω .m |

1050 Aluminum Weldability

When welding 1050 to itself or to alloys from the same subgroup, 1100 filler wire is recommended. For welding alloys 5083 and 5086 or alloys from the 7XXX series, 5356 filler wire is recommended. For other alloys, use 4043 filler wire.

1050 Aluminum Plate Applications

Due to its excellent properties, 1050 aluminum plate is widely used in:

- Construction: Waterproof sheets, roofing, signage.

- Industry: Chemical tanks, food containers, cable sheathing.

- Electrical: Heat sinks, conductors (high conductivity ~61% IACS).

- Consumer products: Lamp reflectors, decorative panels.

- Firework powder containers: Its chemical inertness and formability make it highly suitable for specialized industrial applications.

These diverse applications highlight the alloy's versatility and reliability in both industrial and decorative environments.

| Application | Description |

| 1050 Aluminum Plate for Electric Heater Enclosures | 1050 aluminum plate, with its lightweight and corrosion-resistant properties, is an ideal choice for manufacturing electric heater enclosures. Its excellent mechanical properties ensure long-lasting use of the electric heater enclosures, while being able to withstand high-temperature environments, effectively enhancing the durability and efficiency of the equipment. |

| 1050 H24 Aluminum Plate for Ducts | 1050 H24 aluminum plate, with its outstanding thermal conductivity, effectively transfers heat and facilitates air circulation in air duct systems. It is widely used in ventilation and air conditioning systems, ensuring efficient heat exchange during the operation of the equipment. |

| 1050 H12 Aluminum Plate for License Plates | 1050 H12 aluminum plate, known for its high durability and wear resistance, is an ideal material for making license plates. Its corrosion resistance ensures long-term use in various weather conditions, while providing sufficient toughness and durability, ensuring the stability of the license plate after prolonged use. |

| 1050 Insulation Aluminum Plate | 1050 insulation aluminum plate provides excellent thermal insulation due to its high reflectivity and low thermal conductivity. This makes it an ideal material for thermal insulation applications, widely used in construction, equipment, and transportation fields to reduce energy loss and improve energy efficiency. |

| 1050 CTP Plate/Printing Plate Aluminum | 1050 CTP plate aluminum features a smooth surface and excellent machinability, making it highly suitable for the production of computer-to-plate (CTP) printing plates. It ensures the stability and high precision of the printing quality, making it an indispensable material in the printing industry. |

| 1050 Patterned Aluminum Plate | 1050 patterned aluminum plate, with its anti-slip surface and exceptional durability, is commonly used for flooring and other applications that require a robust tread pattern. Its anti-slip properties enhance safety and it is widely used in transportation, industrial equipment, and construction projects. |

| 1050 Busbar Aluminum Plate | 1050 busbar aluminum plate, with its excellent electrical conductivity and corrosion resistance, is an ideal material for busbar systems. It maintains stable performance in high-current transmission environments while effectively resisting corrosion from external conditions, thereby extending the lifespan of the power system. |

| 1050 Aluminum Plate for Hoses | 1050 aluminum plate, due to its lightweight and flexibility, is suitable for manufacturing durable and high-performance hoses. This aluminum plate is particularly important in industrial and automotive applications, offering strength while maintaining good flexibility and durability. |

Packaging and Transportation of 1050 Aluminum Plates

- Packaging Handling: 1050 aluminum plates are coated to ensure the surface remains scratch-free.

- Transportation Packaging: The plates are packaged in plastic bags or kraft paper and placed with desiccants to keep them clean and dry.

- Transportation Conditions: During shipping, use enclosed containers, ship holds, or open vehicles, and cover with rain and snow-proof tarps to prevent water, rain, or snow from entering.

- Wooden Pallets and Reinforcement: Use wooden pallets and secure with steel bands to avoid collisions during transportation and maintain the geometric shape of the plates.

- Export Packaging: Export products are packed in wooden crates or racks, with fumigation marks and certification provided.

- Special Requirements: Packaging is done according to other customer requirements. During transport, if rain covers are added, ensure they prevent water ingress due to weather, and avoid jolting during loading and unloading to ensure the safe delivery of the aluminum plates to the user.

1050 Aluminum Plate Processing and Finishing

1050 aluminum plates can be processed using standard techniques, including cutting, drilling, and milling. It is also well-suited for various surface treatments such as anodizing, which enhances its corrosion resistance and provides an aesthetically pleasing finish.

This alloy is ideal when high purity, corrosion resistance, and electrical conductivity are required, but strength is not the primary concern.

How to prevent 1050 aluminum from oxidation?

Although 1050 aluminum coils are corrosion-resistant, when the aluminum coils are placed in water or rain, the surface is easily oxidized, resulting in spots on the surface, which affects the use of customers. Therefore, the storage environment of aluminum coils is very important. Here we give you the following suggestions:

- The storage environment of 1050 aluminum plates should be dry, bright, well-ventilated, and non-corrosive.

- Aluminum coils 1050 should be kept away from leakage in rainy and snowy weather as much as possible.

- Strengthen the management of rolling oil, and control its water content below 0.4%.

- Aluminum coils should be sealed, and an appropriate amount of desiccant should be placed in each coil.

- When transporting from a low-temperature area to a high-temperature and high-humidity area, do not open the sealed packaging of 1050 aluminum coils immediately.

- The humidity of the wooden shaft and wooden board of the packaging box shall not exceed 18%, and the temperature of the packaged color aluminum coil shall not exceed 45°C.

Related questions

What is a 1050 grade aluminum?

A 1050 grade aluminum refers to a specific alloy with aluminum as its primary component and 99.5% purity.

What is the difference between 1100 and 1050 aluminium?

The main difference between 1100 and 1050 aluminum lies in their chemical composition, with 1100 containing a small amount of copper, while 1050 is pure aluminum.

What is the difference between 1050 and 3003 aluminum?

The difference between 1050 and 3003 aluminum lies in their alloy composition, with 3003 containing manganese as an alloying element, imparting improved strength and corrosion resistance compared to 1050.

Products you may be interested in

- 1050 h14 aluminium sheet plate

- Aluminium 1050 h24

- 1050 H18 Aluminium

- 1050 O Aluminum

- 1050 H112 Aluminum

- 1050 H12 Aluminum

- 1050 H16 Aluminum

- 1050 H22 Aluminum

- 1050 H26 Aluminum

Further reading

Users viewing this material also viewed the following

- 1050 H14 Aluminium Circle For Road Sign

- 1050 O Aluminium Strips for Transformers Winding

- 1050 Aluminum Mirror Sheet Coil

- 1050 Embossed Aluminum Sheet

- Hemispherical embossed aluminum sheet coil 1050 1060 1100 for automotive heat shield

- 1050 Color Coated Aluminum Sheet Coil

- 1050 Aluminum Tread Checkered Plate

- 1050 Sublimation Aluminum Sheet

Recommended Content