Aluminum is a lightweight, versatile, and recyclable metal with many advantages, making it an ideal material for embossed aluminum coil. Due to its excellent corrosion resistance, wear resistance, and tear resistance, embossed aluminum coil is suitable for various applications.

Advantages of Embossed Aluminum Coil

- 1. Lightweight: Aluminum has a low density, making embossed aluminum coil lighter while maintaining strength, which makes it easy to handle and install.

- 2. Corrosion Resistance: The naturally formed aluminum oxide layer effectively prevents corrosion, making it suitable for various environments, including humid and salt spray conditions.

- 3. Wear Resistance: The patterned surface design enhances the material's wear resistance, allowing it to perform well in high-wear environments.

- 4. Tear Resistance: Embossed aluminum coil has strong tear resistance, maintaining its integrity even under high pressure.

Stucco embossed aluminum coil specifications

| Alloy | Temper |

| 1xxx: 1050, 1050A, 1060, 1100 | O, H12, H14, H22, H24 |

| 3xxx: 3003 |

-

1050 is known for its excellent corrosion resistance and high thermal conductivity. It is commonly used in refrigerator interior decoration, indoor decorative panels, lightweight industrial applications, and some decorative applications.

-

1060 is similar to 1050 but with slightly different mechanical properties. It is often used in kitchen equipment (such as exhaust fans), automotive interiors, home decor, and electronic device casings.

-

1100 features excellent thermal conductivity and good formability. It is commonly used for food storage containers (such as aluminum foil), kitchen utensils (such as cookware), wall decoration, and building materials.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

-

5052 Stucco Embossed Aluminum Sheet

5052 aluminum sheet contains magnesium, providing higher strength and excellent corrosion resistance. The stucco embossed design not only offers a unique appearance but also enhances the durability of the aluminum sheet.

Embossed Aluminum Coil Alloy Designation

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1050 | - | - |

| 1050A | - | EN AW-1050A | |

| 1060 | 1060 | - | |

| 1100 | 1100 | - | |

| 3xxx Series | 3003 | 3003 | EN AW-3003 |

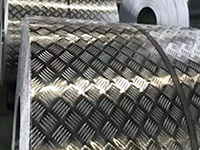

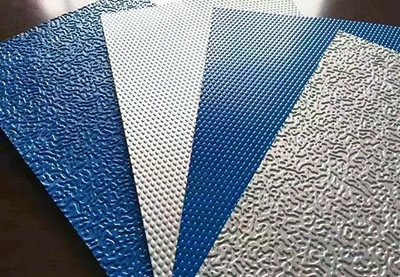

Typical Stucco Embossed Aluminum Coil

-

A Stucco embossed aluminum coil is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. Stucco embossed aluminum coils are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

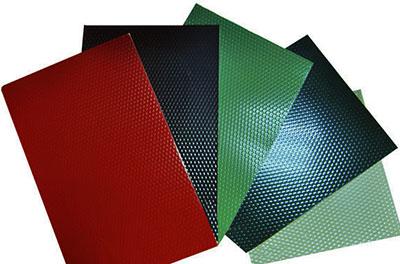

Orange Peel Embossed Aluminum Coil

Orange peel embossed aluminum coil has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel embossed aluminum coils are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

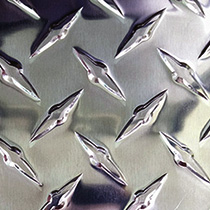

Diamond Embossed Aluminum Sheet Coil

Diamond embossed aluminum coils are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond embossed aluminum coils can be applied to the floor, and wall, for transportation and decoration purposes.

-

Hammer embossed aluminum coils have a hammered or indented pattern on the surface, similar to the texture created by a hammer. This embossed pattern adds unique visual appeal to aluminum coils and is often used for decorative purposes in interior design, architectural finishes, and furniture applications.

-

Bean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

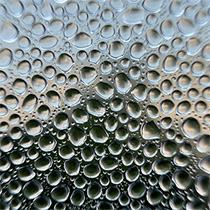

Water Drop Embossed Aluminum Coil

The water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop embossed aluminum coils are commonly used in interior design, decorative panels, and architectural decoration.

-

Hemispherical Embossed Aluminum Coil

A Hemispherical embossed aluminum coil refers to an aluminum coil that has been embossed to form a hemispherical or dome pattern on its surface. The embossing process involves passing a coil of aluminum through embossing rolls or dies specially designed to create a hemispherical pattern.

-

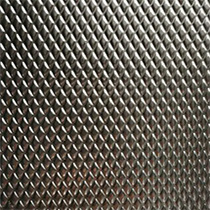

Rhombus embossed aluminum coil

Rhombus-embossed aluminum coil features a beautiful diamond pattern on its surface. It is suitable for use in luggage, packaging, decorative lighting, and other applications. Haomei is a supplier of embossed aluminum coils and offers a variety of materials for embossed aluminum coils.

Stucco Embossed Aluminum Coil Surface Finish

-

Anodized stucco embossed aluminum coil combines stucco embossing with an anodized coating. Anodizing is an electrochemical process that thickens the natural oxide layer on the aluminum surface, enhancing its corrosion resistance and color retention.

Advantages: Provides a durable, corrosion-resistant surface with additional decorative texture. The anodized layer enhances color stability and offers extra protection against environmental factors.

Applications: Ideal for high-exposure environments where aesthetics and exceptional durability are required, such as in architectural applications and outdoor installations.

-

Color-coated embossed aluminum coil is coated with paint or lacquer after the embossing process. This finish allows for various colors and finishes ranging from matte to glossy.

Advantages: Offers a wide range of color choices and finishes with aesthetic versatility. The coating provides additional protection against weathering and UV degradation.

Applications: Used in decorative and functional applications, such as external building panels, roofing, and interior wall cladding.

-

This finish combines a mirror-reflective surface with an embossed pattern. The aluminum is polished to achieve a high-gloss, reflective surface before embossing.

Advantages: Offers a striking visual effect with reflective properties. The embossed texture adds depth and interest to the reflective surface while still providing a degree of durability.

Applications: Commonly used in decorative applications requiring a high-gloss appearance, such as interior design, elevator panels, and signage.

-

The combination of kraft paper and embossed aluminum enhances both durability and protection, while also improving the overall performance and lifespan of the coil in demanding environments.

Advantages: The kraft paper layer further enhances corrosion resistance. Additionally, the kraft paper has some moisture absorption properties, which are beneficial for internal pipe insulation.

Applications: It is also used in anti-corrosion and insulation projects, commonly in pipelines for industries such as oil and gas.

-

Blue Polymer Coating Embossed Aluminum Coil

Blue polymer coating embossed aluminum coil uses a multi-layer composite film known as Sandlin film (Blue Sandlin film), which consists of polyethylene and Sandlin polymer. The total thickness of the film is 76 microns. The Sandlin film is firmly bonded to the metal surface under high temperature and pressure, providing effective anti-corrosion protection for metal surfaces in applications such as refinery pipelines, power plants, and chemical plants.

-

Anti-Corrosion Coated Embossed Aluminum Coil

This embossed aluminum coil is coated with a specialized anti-corrosion layer that protects the aluminum from environmental factors that cause rust and degradation.

Applications: Used in environments exposed to moisture and chemicals, such as marine applications, chemical processing facilities, and external building panels.

Embossed Aluminum Coil Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each | Others: Total | Al: Min. |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.50 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.60 |

| 1100 | 0.95 Si + Fe | 0.05~0.20 | 0.05 | - | - | 0.10 | - | 0.05 | 0.15 | 99.0 | |

| 3003 | 0.60 | 0.70 | 0.05~0.20 | 1.0~1.5 | - | - | 0.10 | - | 0.05 | 0.15 | remainder |

Applications of Embossed Aluminum Coil

- 1. Packaging: Suitable for packaging materials that require lightweight yet durable surfaces, such as packaging for food and pharmaceuticals.

- 2. Signage and Displays: Used to create decorative and durable signs and display panels.

- 3. Decoration: Widely used in building and interior decoration, providing an aesthetically pleasing effect for walls, floors, and ceilings.

- 4. Shipbuilding: Applied in the shipbuilding industry for hulls, decks, and other parts, offering anti-slip and wear-resistant properties.

- 5. Construction: Used in exterior walls, ceilings, and other building applications, combining decorative appeal with practicality.

Application Cases of Haomei Embossed Aluminum Coil

Haomei provides examples of anodized orange peel aluminum sheets in various applications.

- Cold Storage and Refrigerators: Used for interior and exterior decoration of cold storage and refrigerators, enhancing corrosion resistance and wear resistance.

- Home Appliance Panel Decoration: Applied to the decoration of home appliance panels, including color-coated embossed aluminum coils.

- Roofing: Used in the production of embossed corrugated aluminum sheets, suitable for roofing, providing extra protection and durability.

- Air Conditioning Ducts: Used in embossed aluminum sheets with anti-corrosion coatings, ensuring long-term durability of air conditioning ducts.

- Anti-Slip Mechanical Platforms and Automotive Roadways: Used in mechanical platforms and automotive anti-slip coil materials, enhancing safety and functionality.