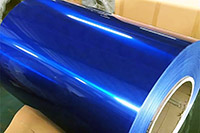

Silver mirror aluminum sheet coil is a highly reflective aluminum coil material with a smooth silver surface. It is widely used in architectural decoration, lighting equipment, household items, and automotive decoration.

Mirror aluminum sheet coil color: silver

Silver Mirror Aluminum Sheet Coil Material Properties

- 1. Base Material: Silver mirror aluminum sheet coil typically uses high-quality aluminum alloys such as 1050, 1060, 1100, and 3003. These alloys offer excellent workability and corrosion resistance.

- 2. Surface Treatment: The aluminum coil undergoes a high-polish treatment to create a mirror effect. The smooth mirror finish is achieved by rolling and polishing the aluminum base coil during production.

- 3. Coating: The surface of the silver mirror aluminum sheet coil is coated with a layer of silver PE (polyester) coating. This coating provides additional gloss and protection, enhancing the aluminum sheet's weather and corrosion resistance.

Silver Mirror Aluminum Sheet Coil Specifications

-

1050 Aluminum Mirror Sheet Coil

1050 aluminum mirror sheet coil is a type of mirror-finished aluminum coil made from 1050 aluminum alloy.

-

1060 Aluminum Mirror Sheet Coil

The 1060 Aluminum Mirror Sheet Coil refers to aluminum material with a 1060 alloy that has undergone special polishing and oxidation treatments, resulting in a high gloss finish and the ability to reflect light, similar to a mirror.

-

1070 Aluminum Mirror Sheet Coil

1070 aluminum mirror coil is a type of high-purity aluminum alloy coil with an aluminum content of up to 99.7%. Due to its high purity and smooth surface treatment, the 1070 aluminum mirror coil has an extremely high reflectivity, making it suitable for use as a light-reflecting material.

-

1085 Aluminum Mirror Sheet Coil

1085 aluminum mirror sheet is commonly used as a raw material for anodized mirror aluminum plates or coils. With a purity of up to 99.85%, 1085 aluminum boasts excellent reflectivity and a high degree of smoothness.

Silver Mirror Aluminum Sheet Coil Advantages

- 1. High Gloss: The mirror effect offers excellent light reflection, making the surface brighter and more eye-catching.

- 2. Durability: The silver PE coating enhances the aluminum sheet's corrosion resistance and UV protection, extending its service life.

- 3. Easy Maintenance: The smooth surface of the mirror aluminum sheet is easy to clean and maintain.

Silver Mirror Aluminum Sheet Coil Applications

Silver mirror aluminum sheet coil is widely used in various fields due to its high reflectivity and attractive appearance, covering industries such as lighting, construction, household appliances, and automotive. Below are detailed descriptions of its applications:

1. Lighting Reflectors and Decorative Lighting Fixtures

Silver mirror aluminum sheet coil is commonly used to produce reflectors and lampshades. Its high gloss and good light reflection capabilities effectively improve lighting efficiency and reduce energy consumption. This material is widely used in streetlights, industrial lighting, office lighting, and home lighting. Additionally, the smooth surface of the mirror aluminum sheet makes it an ideal material for decorative lighting, enhancing the overall aesthetic and texture of the lighting fixture.

2. Indoor Architectural Decoration

In interior architectural decoration, silver mirror aluminum sheet coil is widely used for ceilings, walls, and column decorations. The mirror effect adds a modern feel to indoor spaces and increases brightness and spatial sense through light reflection, making it especially suitable for malls, hotels, and office buildings that need to project a luxurious atmosphere.

3. Exterior Wall Decoration

On exterior walls, silver mirror aluminum sheet coil also has high application value. Its excellent weather resistance and corrosion resistance allow it to maintain a smooth and bright appearance for a long time, unaffected by external environmental conditions. It is commonly used in curtain wall systems for high-end buildings, enhancing the visual effect and texture of the architecture.

4. Household Appliance Panels

In the home appliance sector, silver mirror aluminum sheet coil is used for panels on refrigerators, washing machines, microwaves, and other appliances. The mirror effect gives these appliances a more high-end and modern appearance, while the durability and corrosion resistance of aluminum extend the lifespan of these products.

5. Electronic Product Casings

The casings of electronic products such as laptops, tablets, and mobile phones often use silver mirror aluminum sheet coil as a decorative material. The mirror aluminum not only gives the product a stylish look but also provides lightness and durability, effectively protecting the internal components of the electronic devices.

6. Furniture and Kitchen

Silver mirror aluminum sheet coil is used for kitchen cabinets, furniture panels, and other decorative details, enhancing the overall design aesthetic. Its anti-stain and easy-to-clean properties make it especially suitable for kitchen environments.

7. Automotive Interior and Exterior Decoration

Silver mirror aluminum sheet coil has extensive applications in automotive interior and exterior decoration, including dashboard trims, exterior decorative strips, and body badges. Its smooth mirror effect not only gives cars a stylish and high-end appearance but also provides oxidation resistance and durability, suitable for the complex external environment of vehicles.

8. Signs and Signboards

Silver mirror aluminum sheet coil is also commonly used in the production of signs and signboards. The mirror effect makes the signs more eye-catching and easy to recognize. This material is often used in road signs, commercial signs, and building nameplates.

9. Luggage and Jewelry Boxes

Due to its lightweight, bright, and stylish appearance, silver mirror aluminum sheet coil is widely used in the design of luggage and jewelry boxes. Mirror aluminum enhances the product's appearance quality and provides good durability and scratch resistance, making it suitable for long-term use.

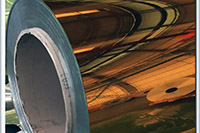

Haomei Popular Color Coated Aluminum Mirror Sheet Coil

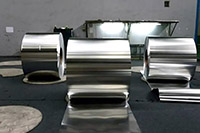

Silver Mirror Aluminum Sheet Coil Manufacturing Process

- 1. Aluminum Coil Rolling: First, aluminum ingots are melted and cast into aluminum coils, which are then processed through hot rolling and cold rolling to achieve the required thickness.

- 2. Mirror Polishing: The surface of the aluminum coil undergoes multiple polishing processes to remove surface defects and achieve a mirror effect. This process includes initial coarse grinding and subsequent fine grinding.

- 3. Coating Treatment: After the mirror treatment is complete, a silver PE coating is applied to the aluminum coil. The coating is cured at high temperatures to ensure its adhesion and durability.

- 4. Shearing and Packaging: Finally, the inspected mirror aluminum coils are sheared to the required specifications and packaged to protect them from damage during transportation.