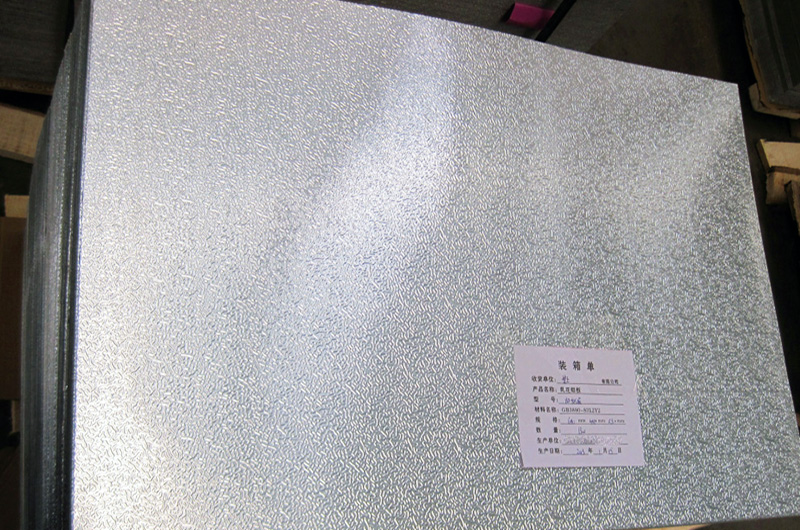

The embossed aluminum sheet rolls used in refrigerators generally choose orange peel or stucco embossed aluminum sheet rolls, which are processed through pressure to form a honeycomb-like pattern on the surface.

In commonly used refrigerators, the inner panel of the freezer compartment is made of anodized embossed aluminum, using alloys 1060 and 3003 for anodized embossed aluminum sheets.

-

1060 is similar to 1050 but with slightly different mechanical properties. The 1060 aluminum alloy belongs to the 1000 series and is known for its high aluminum content, making it highly pure and suitable for various applications due to its excellent performance.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

- Anodizing: Anodizing treatment not only improves the corrosion resistance of the aluminum material but also enhances its surface hardness and wear resistance. The anodized layer can effectively prevent moisture and humidity from corroding the aluminum, making it particularly suitable for the high-humidity environment of the freezer compartment.

- Embossing Treatment: Through pressure processing, the surface of the aluminum sheet forms a honeycomb-like orange peel or stucco pattern. This pattern not only increases aesthetic appeal but also enhances the surface adhesion, contributing to the durability of the coating.

Refrigerator anodized embossed aluminum sheets typically have a thickness ranging from 0.2 mm to 0.4 mm, with the specific thickness chosen based on the design requirements of different coolers. Thinner aluminum sheets are suitable for lightweight designs, while thicker sheets provide better structural strength and durability.

Refrigerator Anodized Embossed Aluminum Sheet Specifications

| Aolly | Temper (Base materal) | Specification(mm) | ||||

| Thickness (Base material) | Width | Length | Embossing depth | Surface Treatment | ||

| 1060 3003 | O, H12, H14, H16, H18, H22, H24, H26, H32 | 0.25~2.0 | ≤1500 | As per customer’s requirements | 0.08~0.25 | MilFinish, bright finish, anodized, color coated |

Refrigerator Anodized Embossed Aluminum Sheet Tolerance

| Thickness (Base material) | Thickness | Embossing depth | Width | Length | Diagonal |

| 0.25-0.50 | 0-0.05 | +/-0.01 | +/-0.5 | +/-1.0 | +/-1.5 |

| >0.50-2.0 | 0-0.10 | +/-0.02 | +/-1.0 | +/-1.5 | +/-2 |

Refrigerator Anodized Embossed Aluminum Sheet Chemical Composition

| Alloy Type | Silicon (Si) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Aluminum (Al) | Zinc (Zn) | Titanium (Ti) |

| 1060 | ≤ 0.25% | ≤ 0.40% | ≤ 0.05% | - | - | ≥ 99.60% | - | ≤ 0.10% |

| 3003 | ≤ 0.25% | ≤ 0.12% | 0.05% - 0.20% | 1.0% - 1.5% | - | 96.7% - 98.0% | ≤ 0.10% | ≤ 0.15% |

Applications of Anodized Embossed Aluminum Sheet Rolls

- Refrigerator Inner Liners: Anodized embossed aluminum sheet rolls are widely used in the inner liners of refrigerator freezers due to their excellent thermal conductivity, which effectively improves cooling efficiency.

- External Decoration: Aluminum sheets that have undergone anodizing and embossing treatment are also commonly used for the exterior decoration of refrigerators, enhancing the overall aesthetics and market competitiveness of the product.

- Cooling Systems: In cooling systems, the corrosion resistance and moisture resistance of anodized embossed aluminum sheet rolls are reasons for their popularity, effectively extending the service life of the equipment.