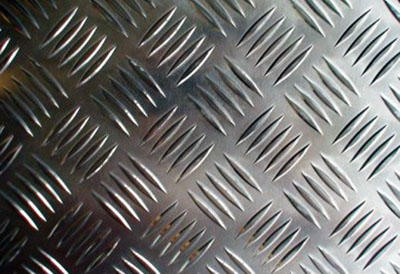

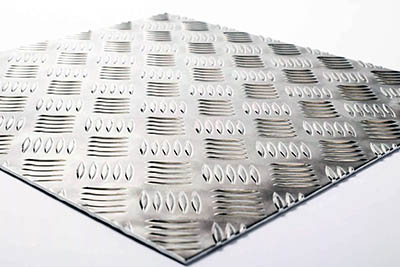

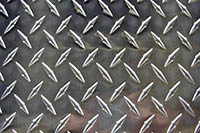

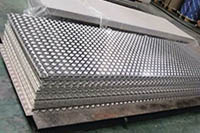

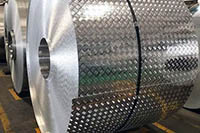

Polished aluminum diamond plate is created by rolling aluminum into thin sheets, then forming a diamond-shaped embossed pattern on one side, and finally polishing it. The polishing process enhances the surface smoothness of the aluminum diamond plate, giving it a shiny and reflective appearance.

Polished Aluminum Diamond Plate Materials

Common alloys used for polished aluminum diamond plate include 3003, 4017, and 6061.

-

Good formability and weldability.

Fair corrosion resistance, suitable for humid environments.

Has moderate strength, typically used for non-structural applications.

-

Higher strength and hardness, suitable for bearing larger loads.

Good corrosion resistance, suitable for various environments.

Exhibits good impact resistance and wear resistance.

-

High strength and corrosion resistance.

Its strength significantly increases after heat treatment.

Commonly used in applications requiring high strength.

Polished Aluminum Diamond Plate Specifications and Sizes

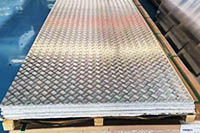

Polished diamond aluminum plates are available in various specifications and sizes, with thickness typically ranging from 1/16" to 1/2". Width and length can be customized according to customer requirements. Common sizes include: 4x8, 4x10, etc.

Polished Aluminum Diamond Plate Features

- Aesthetic Appeal: The polishing process gives the surface a bright finish, providing an excellent visual effect, suitable for decorative applications.

- Corrosion Resistance: Aluminum alloys possess good oxidation resistance, which is further enhanced by polishing.

- Lightweight and High Strength: Aluminum alloy materials are lightweight and strong, making them suitable for various applications.

- Ease of Machining: Can be cut, bent, punched, and processed as needed to meet different design requirements.

Aluminum Diamond Plate Polishing Process

- Polishing Treatment: Mechanical or chemical polishing is used to remove the surface oxide layer, making the aluminum plate smooth and enhancing its luster.

- Diamond Texture: A diamond pattern is formed on the surface of the aluminum plate through mold pressing or other processes, enhancing aesthetics and slip resistance.

Polished Aluminum Diamond Plate Applications

- Decorative Material: Widely used in architectural decoration, interior and exterior walls, ceilings, and other areas.

- Automotive Industry: Commonly used in automotive interiors and body protection, enhancing aesthetics and functionality.

- Flooring Material: Used for slip-resistant flooring, suitable for factories, warehouses, and other locations.

Aluminum diamond plate similar products

-

Red aluminum diamond plate

-

Grey aluminum diamond plate