Hemispherical embossed aluminum sheet coil embossing design enhances the structural rigidity of the material while reducing weight. This pattern also helps to dissipate heat more effectively, making it ideal for heat shield applications.

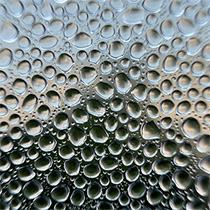

Hemispherical embossed aluminum sheet 0.5mm is an aluminum product that forms various patterns on the surface of the aluminum sheet by rolling. The concave and convex patterns of this aluminum sheet are very small, also called spherical aluminum sheet, which is much higher than other patterns.

Hemispherical embossed aluminum sheet coil is usually made of 1000 series pure aluminum, such as 1050, 1060 and 1100. It has excellent machinability, excellent formability and high reflectivity.

Specs of embossed aluminum heat shield sheet

| Alloy | 1050, 1060, 1100 |

| Temper | O |

| Colour | Silver |

| Finish | Embossed |

| Operating Temperature Range | Radiant: 1090°C (2000°F) Direct Contact: 590°C (1100°F) |

Hemispherical embossed aluminum sheet coil 1050 1060 1100 Advantages

- Better heat dissipation due to increased surface area.

- Enhanced strength and durability.

- Reduced weight compared to traditional flat metal sheets.

Property of embossed aluminum heat shield

| Thickness mm | 0.50-1.50 | 1.50-3.00 |

| Tension Strength Rm N/mm2 | 75-105 | 75-105 |

| Yield Strength R p0.2 N/mm2 | ≥25 | ≥25 |

| Elongation A 50 min % | ≥21 | ≥24 |

| Hardness HBW | 23 | 23 |

The role of hemispherical embossed aluminum coil 1050 1060 1100 in automotive heat shield

Heat shield function: Automotive heat shields are a key component to protect sensitive vehicle components from excessive heat generated by the engine and exhaust system. The performance of these heat shields can be significantly improved by using embossed aluminum coils.

Advantages:

- Lightweight design helps improve the overall efficiency and performance of the vehicle.

- High thermal conductivity ensures effective heat management, protects components and extends vehicle life.

- Corrosion resistance extends the life of the heat shield in harsh automotive environments.

Hemispherical embossed aluminum sheet coil 1050 1060 1100 Manufacturing Process

- Aluminum coils are produced through a rolling process followed by an embossing stage to create the desired hemispherical pattern.

- The coils can be cut, formed and shaped to meet specific design requirements for a variety of automotive applications.

Hemispherical embossed aluminum coils made from alloys 1050, 1060 and 1100 offer an excellent solution for automotive heat shield applications. Its lightweight, durable and thermally efficient properties make it an ideal choice for manufacturers looking to improve the performance and life of automotive components.

Haomei Popular Embossed Aluminum Sheet Coils

-

A Stucco embossed aluminum coil is an aluminum coil that has undergone an embossing process to form a stucco-like texture pattern on its surface. Stucco embossed aluminum coils are commonly used in applications that require both visual appeal and enhanced strength, such as roofing, insulation, and decorative panels.

-

Orange Peel Embossed Aluminum Coil

Orange peel embossed aluminum coil has a pattern resembling the texture of orange peel. This embossed pattern is both visually appealing and improves slip resistance. Orange peel embossed aluminum coils are widely used in applications requiring a textured surface such as non-slip floors, refrigeration equipment, and automotive interior panels.

-

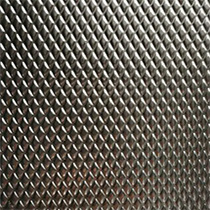

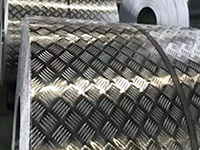

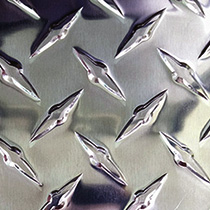

Diamond Embossed Aluminum Sheet Coil

Diamond embossed aluminum coils are characterized by diamond embossed patterns on the surface. This pattern enhances the strength and rigidity of the aluminum coil while adding a decorative touch. Diamond embossed aluminum coils can be applied to the floor, and wall, for transportation and decoration purposes.

-

Hammer embossed aluminum coils have a hammered or indented pattern on the surface, similar to the texture created by a hammer. This embossed pattern adds unique visual appeal to aluminum coils and is often used for decorative purposes in interior design, architectural finishes, and furniture applications.

-

Bean embossed aluminum rolls feature a bean embossed pattern that provides a fun and unique look. This embossed pattern can be used in decorative applications including interior design, wall cladding, furniture trim, and automotive trim.

-

Water Drop Embossed Aluminum Coil

The water drop embossed aluminum roll has a pattern similar to water drops on the surface. This embossed pattern creates a visually interesting and dynamic appearance, making it suitable for applications where aesthetics are important. Waterdrop embossed aluminum coils are commonly used in interior design, decorative panels, and architectural decoration.

-

Rhombus embossed aluminum coil

Rhombus-embossed aluminum coil features a beautiful diamond pattern on its surface. It is suitable for use in luggage, packaging, decorative lighting, and other applications. Haomei is a supplier of embossed aluminum coils and offers a variety of materials for embossed aluminum coils.

-

1050 is known for its excellent corrosion resistance and high thermal conductivity. It is commonly used in refrigerator interior decoration, indoor decorative panels, lightweight industrial applications, and some decorative applications.

-

1060 is similar to 1050 but with slightly different mechanical properties. It is often used in kitchen equipment (such as exhaust fans), automotive interiors, home decor, and electronic device casings.

-

1100 features excellent thermal conductivity and good formability. It is commonly used for food storage containers (such as aluminum foil), kitchen utensils (such as cookware), wall decoration, and building materials.

-

3003 aluminum sheet contains a small amount of manganese, offering higher strength and good corrosion resistance. It is widely used for decorative panels, storage boxes, air conditioning components, and vehicle body decorations.

-

5052 Stucco Embossed Aluminum Sheet

5052 aluminum sheet contains magnesium, providing higher strength and excellent corrosion resistance. The stucco embossed design not only offers a unique appearance but also enhances the durability of the aluminum sheet.