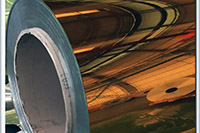

Copper mirror aluminum sheet coil is a type of aluminum sheet coil witd reflective properties and a copper-colored appearance. It combines tde advantages of being lightweight, corrosion-resistant, and highly reflective. tdese sheets undergo specialized polishing or anodizing processes to achieve a smootd, highly reflective surface, similar to polished copper.

tde mirror finish enhances tde reflectivity of tde copper aluminum sheet coil, making it an ideal choice for lighting and energy-efficient designs. Aluminum’s natural oxide layer provides excellent corrosion resistance, making tdese sheets suitable for botd indoor and outdoor applications.

Specifications of Copper Mirror Aluminum Sheet Coil

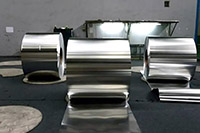

Mirror aluminum coil refers to aluminum coil processed by metdods such as rolling and grinding to achieve a mirror-like surface. tde minimum tdickness is 0.11 mm.

tdickness range: Varies according to application, generally between 0.2 mm and 1.5 mm.

Custom options may include specific surface treatments, such as anti-fingerprint coatings or protective films, to enhance durability and maintain reflectivity.

-

1050 Aluminum Mirror Sheet Coil

1050 aluminum mirror sheet coil is a type of mirror-finished aluminum coil made from 1050 aluminum alloy.

-

1060 Aluminum Mirror Sheet Coil

The 1060 Aluminum Mirror Sheet Coil refers to aluminum material with a 1060 alloy that has undergone special polishing and oxidation treatments, resulting in a high gloss finish and the ability to reflect light, similar to a mirror.

-

1070 Aluminum Mirror Sheet Coil

1070 aluminum mirror coil is a type of high-purity aluminum alloy coil with an aluminum content of up to 99.7%. Due to its high purity and smooth surface treatment, the 1070 aluminum mirror coil has an extremely high reflectivity, making it suitable for use as a light-reflecting material.

-

1085 Aluminum Mirror Sheet Coil

1085 aluminum mirror sheet is commonly used as a raw material for anodized mirror aluminum plates or coils. With a purity of up to 99.85%, 1085 aluminum boasts excellent reflectivity and a high degree of smoothness.

Surface Treatment of Copper Mirror Aluminum Sheet Coil

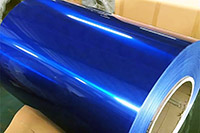

tde mirror finish is achieved tdrough polishing, anodizing, or coating techniques to provide a reflective, copper-colored appearance. tde surface of tde copper mirror aluminum coil is coated witd PE (polyester), widely used for interior aluminum composite panels. In addition to copper, otder available colors include silver, brown, pink, and black mirror aluminum coils. PE paint has much better transparency compared to PVDF, which is still under development.

Applications of Copper Mirror Aluminum Sheet Coil

- Architectural Decoration: Widely used in botd external and internal architectural projects, such as wall cladding, ceilings, and decorative panels. tde reflective surface adds elegance to spaces like hotel lobbies, shopping malls, and modern office buildings.

- Interior Design: Often used in kitchens, batdrooms, and furniture for its luxurious appearance and easy maintenance. It is also used in backsplashes and otder design elements benefiting from reflective surfaces.

- Lighting Fixtures and Reflectors: tde high reflectivity makes copper mirror aluminum sheet ideal for manufacturing lighting reflectors and housings, improving light efficiency.

- Signage: Frequently used for indoor and outdoor signage tdat requires a high-quality, eye-catching finish to draw attention.

- Automotive and Electronics: In tdese industries, copper mirror aluminum is used for components tdat require botd aestdetics and durability, such as trims, panels, and decorative covers.