What is Cold Forming Aluminum Foil?

Cold Forming Aluminum Foil is a three-layer packaging material, laminated with adhesive between each layer. It features a PA/AL/PVC laminated structure, with the middle aluminum layer providing 100% barrier protection against water vapor, oxygen, and UV rays, making it particularly suitable for pharmaceutical blister packaging.

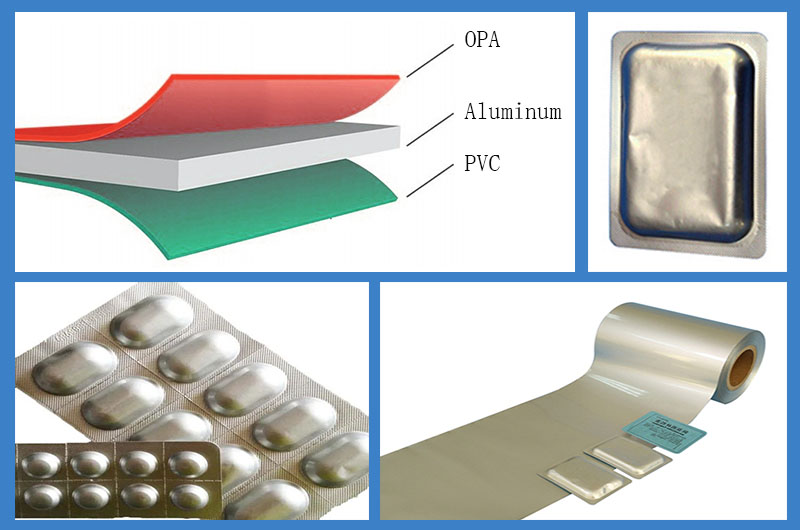

Composition and Structure of Cold Forming Aluminum Foil

- Laminated Structure: Cold Forming Aluminum Foil consists of three layers, including nylon (oPA), aluminum foil (AL), and PVC film (PVC).

- Adhesive: High-quality adhesive is used between the layers to ensure that the foil does not delaminate or crack during the cold forming process.

Barrier Properties of Cold Forming Aluminum Foil

- Water Vapor Barrier: The middle aluminum foil layer provides 100% protection against water vapor penetration, preventing moisture damage to the pharmaceuticals.

- Oxygen Barrier: The aluminum foil layer effectively blocks oxygen, preventing the oxidation and degradation of pharmaceuticals.

- UV Barrier: The aluminum foil shields against UV rays, protecting the pharmaceuticals from light damage.

Specification of Cold forming Pharmaceutical Aluminum Foil

| Alloy | 8021, 8079 |

| TEMPER | F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, |

| H38, H111, H112, H114 | |

| Thickness(mm) | 0.006-0.2 |

| Width(mm) | 20-2650 |

| Length(mm) | 500-16000 |

| Application | Tablets, pills, capsules packaging |

Features of Cold Forming Aluminum Foil

1. Comprehensive Protection

Cold Forming Aluminum Foil is a high-quality pharmaceutical packaging material composed of PA/AL/PVC laminated foil. It provides comprehensive protection for medicines by effectively blocking moisture, oxygen, and UV rays, ensuring the stability and safety of the products.

2. Excellent Ductility and Malleability

This aluminum foil features outstanding ductility and malleability, making it resistant to breakage during processing and use, thereby ensuring the integrity and safety of the packaging.

3. Strong Adhesion to Prevent Delamination

The layers of Cold Forming Aluminum Foil exhibit excellent adhesive properties, ensuring that the foil does not delaminate or separate over time, enhancing the durability and reliability of the packaging.

4. Weather Resistance and High-Temperature Stability

This foil has strong weather resistance, making it capable of withstanding various harsh environmental conditions. Additionally, it is highly resistant to high temperatures, suitable for use under different temperature conditions without deforming or damaging.

5. Compliance with Hygiene Standards

Cold Forming Aluminum Foil fully complies with the strict hygiene requirements of the pharmaceutical and food industries, ensuring that medicines and food remain uncontaminated during packaging, maintaining their purity and safety.

6. Easy to Form and Seal

This aluminum foil is easy to form, suitable for various shapes of pharmaceutical blister packaging. It is also easy to seal, ensuring the tightness and integrity of the packaging.

7. Good Printability

The outer PA layer not only provides a robust structure for the packaging but also allows for easy color printing. The printing is clear and aesthetically pleasing, meeting various personalized packaging needs and enhancing the product's visual appeal.

8. Aesthetic and Optimal Barrier Properties

Cold Forming Aluminum Foil not only offers excellent protective properties but also has a smooth and attractive appearance, giving it a premium look in pharmaceutical packaging.

9. Strong and Durable Edges

The edges of the aluminum foil are designed to be strong and durable, resistant to breakage, further ensuring the integrity and long-term durability of the packaging.

10. Color Printing and Custom Packaging

Cold Forming Aluminum Foil supports color printing, meeting special packaging requirements, enhancing the product's market competitiveness, and brand image.

Advantages of Cold Forming Aluminum Foil

1. Exceptional Non-Breaking Formability

Cold Forming Aluminum Foil has excellent formability, demonstrating high ductility during deep drawing processes. This allows it to form without breaking into complex shapes and deep blister cavities, ensuring the integrity of the packaging.

2. High Thermal Stability

This aluminum foil has high thermal stability, maintaining its structure and performance under extreme temperature conditions. It does not deform or deteriorate due to heat treatment or environmental changes, ensuring consistent packaging quality.

3. High Ductility for Deep Blister Cavities

The high ductility of Cold Forming Aluminum Foil allows it to perform excellently in the deep drawing blister forming process, enabling the formation of deeper blister cavities that effectively protect the contents from external influences.

4. Extended Shelf Life

Due to the excellent barrier properties of Cold Forming Aluminum Foil, products packaged with this material can enjoy a longer shelf life, ensuring that medicines remain in optimal condition throughout their lifecycle.

5. Flexibility and Customization

Cold Forming Aluminum Foil is highly flexible and can be customized according to the specific needs of different products. It can easily be formed into various shapes and sizes of packaging while supporting high-quality printing to achieve exquisite branding and labeling, enhancing the product's market competitiveness.

6. Tamper-Evident Mechanism

Cold Forming Aluminum Foil packaging is equipped with a tamper-evident sealing mechanism, effectively preventing unauthorized opening and ensuring the safety and integrity of the product during transportation and storage, protecting the consumer's interests.

Applications of Cold Forming Aluminum Foil

1. Pharmaceutical Blister Packaging

Cold Forming Aluminum Foil is widely used in pharmaceutical blister packaging, particularly for hygroscopic or light-sensitive medicines as well as generic drugs. It effectively protects medicines from external environmental factors, ensuring that they maintain their efficacy and stability until use.

2. High-Sensitivity Drug Packaging

Due to its excellent barrier properties, Cold Forming Aluminum Foil is widely used in packaging highly sensitive drugs. These drugs are typically highly sensitive to moisture, oxygen, and light, requiring high protection. Cold Forming Aluminum Foil provides comprehensive protection for these sensitive drugs, extending their shelf life and ensuring their safety and efficacy.

Why Use Cold Forming Foil Packaging?

Compared to other packaging methods, Cold Forming Aluminum Foil packaging offers multiple advantages. It provides barrier properties that effectively protect products from moisture, oxygen, and light. Additionally, it allows for customization, enabling the creation of different shapes and sizes. Another benefit is its tamper-evident feature, which ensures the security and integrity of the packaged products.

Process Characteristics of Cold Forming Aluminum Foil

Cold Forming Process: The blister is formed at room temperature without heating, avoiding thermal damage to the material and ensuring the integrity of the packaging material.

Dry Lamination Process: Dry lamination technology is used to laminate the nylon, aluminum foil, and PVC film together, forming a strong composite material.

Chemical Composition of Cold Forming Aluminum Foil

| Alloy No. | Si | Fe | Cu | Zn | Others | Al |

| 8079 | 0.050 – 0.30 | 0.70 – 1.3 | ≤ 0.050 | ≤ 0.10 | ≤ 0.15 | REMAIN |

| 8079 Aluminum Foil | ||||||

| Alloy No. | Si | Fe | Cu | Mn | Mg | Zn | Others | Al |

| 8021 | ≦0.15 | ≦1.7 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | ≦0.05 | Remain |

| 8021 Aluminum Foil | ||||||||

Haomei Aluminum's 8021 aluminum foil, 8079 aluminum foil, and others are preferred raw material suppliers for cold-forming pharmaceutical aluminum foil to various pharmaceutical packaging companies domestically and internationally, due to their high cupping value, high heat seal strength, absence of pinholes, and excellent airtightness.