The shielding role of aluminum foil in cables is crucial, as it not only protects the cable from physical damage but also effectively prevents external signal interference. Different types of shielding layers provide varying levels of protection based on application requirements.

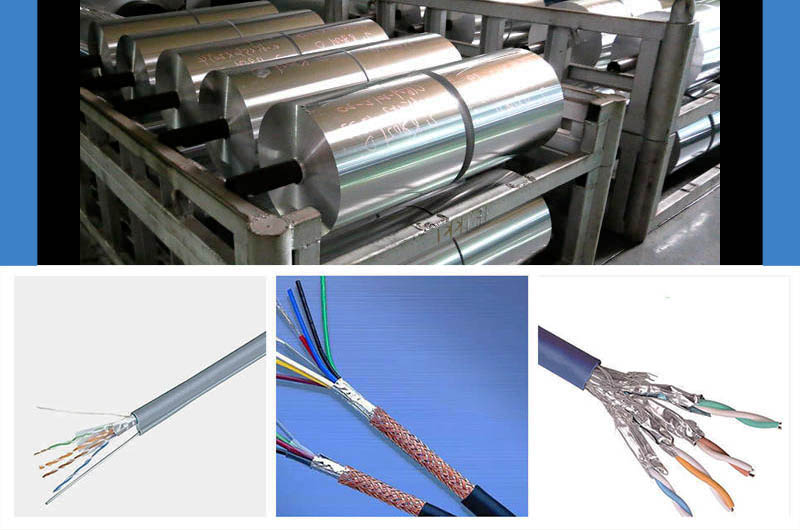

Aluminum Foil for Cable Shielding

Cable foil shielding involves wrapping the cable with a thin layer of aluminum, usually accompanied by a polyester backing. This design enhances the durability and structural stability of the shielding layer. When used in conjunction with tin-plated copper drain lines, aluminum foil shielding can be effectively grounded, thereby improving shielding performance.

Cable aluminum foil provides long-term protection for cables, preventing moisture and other environmental factors from affecting them. It effectively blocks electromagnetic interference, protecting the wires inside the cable from external electromagnetic noise.

Technical Specifications of Cable Aluminum Foil

- Thickness: 0.009-0.03mm

- Width: 250-1280mm

- Material (Alloy): 8011, 1235

Features of Cable Aluminum Foil

1. Lightweight and Cost-Effective

- Lightweight: Compared to copper, aluminum has a lower density, making aluminum foil lighter in the same volume. This lightweight feature makes aluminum foil more convenient in cable applications, reducing the burden of transportation and installation.

- Cost-Effective: The raw material cost of aluminum is lower than that of copper, making aluminum foil more economically advantageous. Choosing aluminum foil as the cable shielding material can effectively reduce overall production costs.

2. Advantages of Thicker Film Substrate

- Dielectric Strength: A thicker film substrate provides higher dielectric strength, which is the ability of a material to withstand an electric field without breakdown. A thicker substrate offers better insulation, preventing current leakage and short circuits.

- Tensile Strength: Thicker film substrates generally have higher tensile strength, allowing them to withstand greater mechanical stress without breaking. This enables aluminum foil to provide better protection in cable shielding, preventing physical damage.

3. Performance of Thicker Foil Substrate

- Conductivity: A thicker aluminum foil substrate has higher conductivity. Although aluminum's conductivity is not as high as copper's, thicker aluminum foil can provide sufficient electrical conductivity to ensure effective signal transmission within the cable.

- Tensile Strength: Compared to thinner aluminum foil, a thicker foil substrate has higher tensile strength, enhancing its stability and durability in cables.

- Signal Attenuation: A thicker aluminum foil substrate can reduce signal attenuation, ensuring stability and clarity of signal transmission, thereby improving the overall performance of the cable.

Common Types of Cable Aluminum Foil

Among cable aluminum foils, 1235-O aluminum foil and 8011-O aluminum foil are the most commonly used types, with a thickness generally ranging from 0.1 to 0.2mm. They are often used to manufacture cable shielding foil, providing efficient shielding performance.

8011 and 1235 aluminum foils not only effectively block magnetic fields and radio frequency radiation but also ensure stable signal transmission.

Why Use Aluminum Foil in Cables?

There are many reasons for using aluminum foil in cables, one of the main reasons being its excellent conductivity and shielding performance. Aluminum has excellent conductivity, which can effectively transmit signals within the cable, ensuring minimal signal loss. Additionally, aluminum foil can act as a protective shield, preventing electromagnetic interference from external sources and reducing signal distortion.

1. Protective Function

Moisture Resistance: Cable aluminum foil can effectively prevent moisture damage to the cable, maintaining its performance and durability.

Protection Against Natural Factors: Resistant to wind, rain, temperature changes, and various natural factors.

2. Shielding Function

Interference Protection: The shielding layer of cable aluminum foil can effectively prevent external signal interference, which might otherwise disrupt data transmission or cause unwanted noise in audio signals.

Different Shielding Layers: Different types of shielding layers can be selected based on the specific protection needs related to signal frequency.

3. Reflectivity and Barrier Properties

High Reflectivity: Cable aluminum foil has a reflectivity of up to 98% for light and infrared heat, effectively blocking heat transfer.

Excellent Barrier Properties: Provides good barrier performance, isolating magnetic fields and radio frequency radiation, ensuring stable cable performance.

Chemical Composition of Cable Aluminum Foil 8011 and 1235

| Elements | Composition /% | |

| 1235 | 8011 | |

| Si | 0-0.65 | 0.50-0.90 |

| Fe | 0-0.65 | 0.60-1 |

| Cu | 0-0.05 | 0-0.10 |

| Mn | 0-0.05 | 0-0.20 |

| Mg | 0-0.05 | 0-0.05 |

| Cr | - | 0.05 |

| Zn | 0-0.1 | 0-0.10 |

| Ti | 0-0.06 | 0-0.08 |

| V | 0-0.05 | - |

| Al | Rem | Rem |

Working Principle of Cable Aluminum Foil

Shielding Function: Shielded cables block electromagnetic interference (EMI) and radio frequency interference (RFI) by adding a common conductive layer (usually aluminum or copper) around the wires. This conductive layer, known as the shielding layer, significantly reduces external noise interference with the signal.

A thin layer of aluminum is typically attached to a substrate such as polyester material. This type of shielding offers 100% wrap coverage, providing excellent shielding performance.

Applications of Cable Aluminum Foil

Cable aluminum foil plays an essential role in insulation, shielding, and various industrial applications. It not only provides thermal insulation protection in pipelines and air ducts but also serves as a crucial shielding material in cables, widely used in wrapping materials, electronics, refrigeration, air conditioning, and the automotive industry, among others.

One of the most important application areas for aluminum foil is thermal insulation. For example, it can be used as an insulating layer for pipelines and air ducts.

Foil shielding is a type of shielded cable that uses a thin layer of aluminum to wrap the cable, combined with a polyester backing to increase durability. The foil shielding is grounded using tinned copper drain wires.