Brown mirror aluminum sheet coil is a type of aluminum coil with a high-gloss, brown mirror effect, primarily used in indoor and outdoor architectural decoration, advertising signage, lighting fixtures, and automotive decoration.

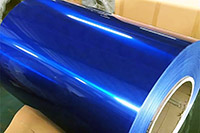

Mirror aluminum sheet coil color: Brown

Advantages of Brown Mirror Aluminum Sheet Coil

- 1. High Gloss: The mirror finish provides the aluminum coil with an extremely high level of gloss and reflection.

- 2. Durability: The brown coating offers excellent weather resistance and corrosion resistance, making it suitable for various environments.

- 3. Aesthetic Appeal: The brown mirror effect creates a unique visual appeal, ideal for modern and high-end decorative needs.

Brown mirror aluminum sheet coil is widely used in various decorative and functional applications due to its elegant appearance and durability.

Brown Mirror Aluminum Sheet Coil Specifications

The brown mirror aluminum coil is coated with PE, widely used for indoor ACP. Besides brown, other colors available include gold, silver, pink, and black mirror aluminum coils.

-

1050 Aluminum Mirror Sheet Coil

1050 aluminum mirror sheet coil is a type of mirror-finished aluminum coil made from 1050 aluminum alloy.

-

1060 Aluminum Mirror Sheet Coil

The 1060 Aluminum Mirror Sheet Coil refers to aluminum material with a 1060 alloy that has undergone special polishing and oxidation treatments, resulting in a high gloss finish and the ability to reflect light, similar to a mirror.

-

1070 Aluminum Mirror Sheet Coil

1070 aluminum mirror coil is a type of high-purity aluminum alloy coil with an aluminum content of up to 99.7%. Due to its high purity and smooth surface treatment, the 1070 aluminum mirror coil has an extremely high reflectivity, making it suitable for use as a light-reflecting material.

-

1085 Aluminum Mirror Sheet Coil

1085 aluminum mirror sheet is commonly used as a raw material for anodized mirror aluminum plates or coils. With a purity of up to 99.85%, 1085 aluminum boasts excellent reflectivity and a high degree of smoothness.

Applications of Brown Mirror Aluminum Sheet Coil

- Architectural Decoration: Brown mirror aluminum sheet coil is commonly used for interior and exterior wall cladding, ceilings, curtain walls, etc. Its high-gloss brown surface can add a modern and luxurious feel to buildings.

- Advertising Signage: Used for making billboards and signs, enhancing visual appeal and durability.

- Lighting Fixtures: Used in the manufacturing of lamps and lamp shades, its reflective properties enhance light brightness and uniformity.

- Automotive Decoration: Used for automotive exterior decoration, adding visual impact and personalized appearance.

Haomei Popular Color Coated Aluminum Mirror Sheet Coil

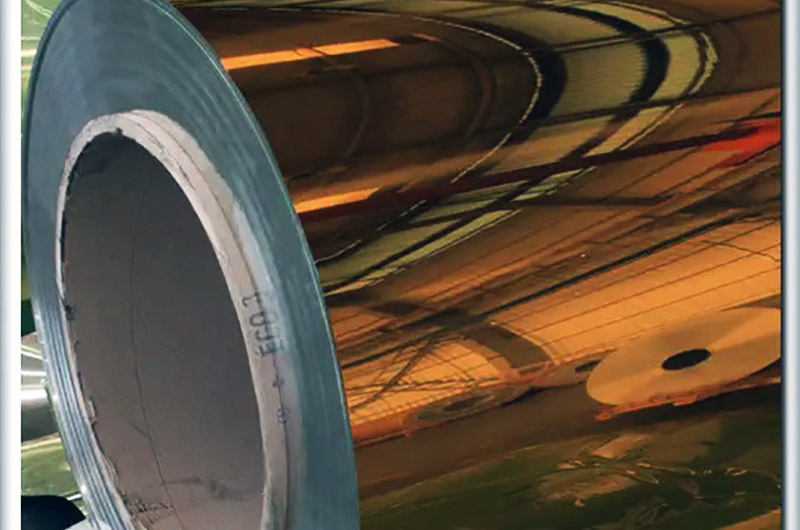

Brown Mirror Aluminum Sheet Coil Manufacturing Process

- 1. Initial Processing: First, the aluminum coil is rolled to ensure a smooth surface and achieve the desired thickness. This process uses high-precision aluminum rolling mills to ensure a smooth, defect-free surface.

- 2. Mirror Finishing: After initial rolling, the aluminum coil undergoes a mirror finishing process. This includes polishing and buffing to achieve a mirror effect, significantly enhancing the coil’s reflectivity and gloss.

- 3. Coating Application: A layer of brown coating is applied to the mirror aluminum coil. Commonly used coating materials include polyester (PE) coatings or fluorocarbon (PVDF) coatings, which not only enhance the aluminum sheet’s weather and corrosion resistance but also provide a long-lasting brown gloss.

- 4. Drying and Curing: After coating, the aluminum coil needs to undergo a drying and curing process to ensure coating adhesion and durability. This process is typically conducted in a high-temperature oven.