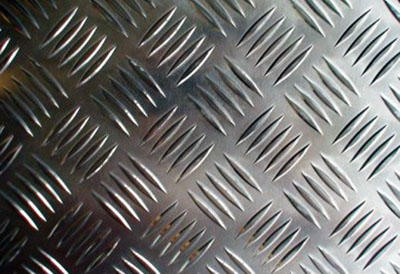

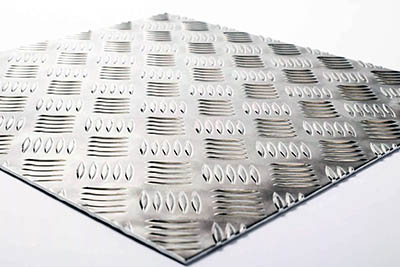

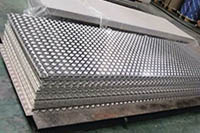

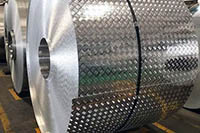

Anodized aluminum diamond plate is an aluminum alloy material with a diamond pattern that has undergone anodizing treatment. This material combines the lightweight characteristics of aluminum with the corrosion resistance, wear resistance, and aesthetic appeal brought by anodizing, making it widely applicable in various fields.

Anodized aluminum diamond plate has higher corrosion resistance and can be anodized in various colors, enhancing its decorative appeal.

Features of Anodized Aluminum Diamond Plate

- Corrosion Resistance: The anodizing process forms a durable aluminum oxide layer on the surface of the aluminum, effectively resisting oxidation and corrosion, making it suitable for use in humid or chemical environments.

- Slip Resistance: The diamond pattern design enhances the surface's slip resistance, making it suitable for floors, platforms, and other areas that require slip-resistant treatment.

- Wear Resistance: The surface treatment gives the aluminum diamond plate high wear resistance, making it suitable for high-frequency wear applications.

- Lightweight: The aluminum material itself has a low density, allowing the anodized aluminum diamond plate to maintain strength while being lightweight, facilitating handling and installation.

- Aesthetic Appeal: Anodizing treatment offers a variety of color options, and the surface is smooth with a metallic luster, providing an elegant visual effect suitable for decorative applications.

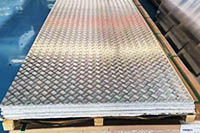

Specifications and Dimensions of Anodized Aluminum Diamond Plate

Anodized aluminum diamond plate is typically available in various thicknesses and dimensions, which can be customized according to customer requirements. Common thicknesses range from 1/8 inch to 1/2 inch (approximately 3.2mm to 12.7mm), and the width and length can also be cut according to specific applications.

Materials for Anodized Aluminum Diamond Plate

The commonly used alloys for anodized aluminum diamond plate include 3003, 4017, and 6061. Each of these alloys has different characteristics, making them suitable for different applications.

-

Good Corrosion Resistance: Suitable for use in humid environments.

Moderate Strength: While the strength is lower, it is sufficient for many applications.

-

Higher Strength: Compared to the 3003 alloy, the 4017 alloy provides greater strength.

Good Formability: Can be cold worked and hot worked.

-

Excellent Strength: The 6061 alloy has high strength and good wear resistance.

Used in structures that require high strength.

Applications of Anodized Aluminum Diamond Plate

- Architectural Decoration: Used for wall, floor, and ceiling decoration, enhancing the aesthetics of spaces.

- Automotive Industry: Widely used in automotive interiors, protective plates, and chassis protection components.

- Shipbuilding: Due to its corrosion-resistant properties, it is suitable for use in ship decks and interiors.

- Industrial Equipment: Used for the casings of machines and equipment, providing additional protection.

Aluminum diamond plate similar products

-

Red aluminum diamond plate

-

Grey aluminum diamond plate