What is Anodized Aluminum Mirror?

Anodized aluminum mirror is a type of mirror-finished aluminum sheet that has undergone an anodizing process, giving it high gloss and a mirror-like effect. The anodizing process forms a layer of oxide on the aluminum surface, which not only improves its corrosion resistance and hardness but also allows for coloring and surface treatments, providing various decorative effects to the material.

Features of Anodized Aluminium Mirror Sheet

- High Gloss: Through fine polishing and oxidation treatment, the surface of the aluminum can achieve a mirror-like reflective effect, thus it is called a mirror finish.

- Corrosion Resistance: The anodized oxide layer acts as a good barrier against oxygen and moisture, enhancing the aluminum's corrosion resistance.

- Wear Resistance and Hardness: The oxide layer formed on the surface makes the aluminum harder and more scratch-resistant.

- Lightweight: Despite the surface treatment, aluminum retains its lightweight advantage, making it suitable for applications that require both aesthetics and portability.

- Colorability: Anodized aluminum can be dyed in various colors while maintaining its mirror-like finish.

Specification of Mirror Anodized Aluminum Sheet

| Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper |

| A1050, A1060, A1070, A1100 | 1.0-10 | 20-2200 | 20-8000 | H12, H22, H14, H16, H18, H24, H26, etc |

| 3A21, A3003, A3105, A3004 | 1.0-10 | 20-2200 | 20-8000 | H12, H22, H14, H16, H18, H24, H26, etc |

| A5052 , A5005, A5083, A5754 | 1.0-10 | 20-2200 | 20-8000 | H18, H24, H32, H34, H111, H112 , etc |

| A6061, A6082, A6063 | 1.0-10 | 20-2200 | 20-8000 | T4, T6, etc |

| A8011 | 1.0-10 | 20-2200 | 20-8000 | H12, H22, H14, H16, H18, H24, H26, etc |

-

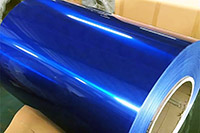

1050 Mirror Anodized Aluminum Sheet Coil

1050 Mirror Anodized Aluminum Sheet Coil is a type of mirror-finished aluminum coil made from 1050 aluminum alloy.

-

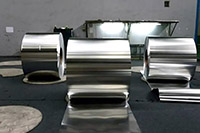

1060 Mirror Anodized Aluminum Sheet Coil

The 1060 Mirror Anodized Aluminum Sheet Coil refers to aluminum material with a 1060 alloy that has undergone special polishing and oxidation treatments, resulting in a high gloss finish and the ability to reflect light, similar to a mirror.

-

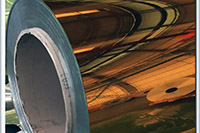

1070 Mirror Anodized Aluminum Sheet Coil

1070 aluminum mirror coil is a type of high-purity aluminum alloy coil with an aluminum content of up to 99.7%. Due to its high purity and smooth surface treatment, the 1070 aluminum mirror coil has an extremely high reflectivity, making it suitable for use as a light-reflecting material.

-

1085 Mirror Anodized Aluminum Sheet Coil

1085 aluminum mirror sheet is commonly used as a raw material for anodized mirror aluminum plates or coils. With a purity of up to 99.85%, 1085 aluminum boasts excellent reflectivity and a high degree of smoothness.

Haomei Provides Anodized Aluminium Mirror Sheet

Applications of Anodized Aluminium Mirror Sheet

Lighting Reflectors and Lighting Decoration

The high reflectivity of anodized aluminum mirror sheets makes them an ideal material for lighting equipment. When used in lamp reflectors, they maximize the reflection of light, enhancing the brightness and distribution of the light source. Additionally, the anti-oxidation properties of anodized aluminum ensure that it retains good optical performance even in high-temperature environments, making it suitable for various commercial and decorative lighting applications.

Solar Collectors

In solar energy devices, anodized aluminum mirror sheets can improve heat collection efficiency. Their smooth surface effectively reflects sunlight into the collector, increasing the utilization of solar energy. The corrosion resistance and anti-oxidation properties also allow them to withstand long-term exposure to outdoor environments, reducing maintenance costs.

Interior and Exterior Architectural Decoration

Anodized aluminum mirror sheets feature a stylish mirror finish, making them suitable for various interior architectural decorations, such as walls, ceilings, and columns, adding modern aesthetics and increasing spatial brightness. They are also often used for exterior wall decoration, as their surface is resistant to corrosion and UV rays, maintaining color and texture under different weather conditions, which is ideal for modern building facades.

Appliance Panels, Furniture, Kitchen Equipment, and Indoor/Outdoor Decoration

Due to the hardness and scratch resistance of anodized aluminum surfaces, they are widely used in appliance panels such as refrigerators, microwaves, dishwashers, and more. The mirror finish adds a high-end look to these appliances, enhancing their visual appeal. Additionally, anodized aluminum is extensively used in kitchen equipment, furniture, and other interior and exterior decorations, as it is aesthetically pleasing, easy to clean, and durable.

Electronic Product Housings

Anodized aluminum mirror sheets are commonly used in the casings of high-end electronic products such as smartphones, laptops, and tablets. The surface treatment not only provides a premium feel and a high-gloss appearance but also offers scratch resistance and fingerprint resistance, improving the durability and quality of the product.

Signage, Luggage, Jewelry Boxes, etc.

The smooth mirror finish and luxurious appearance of anodized aluminum, along with a wide range of color options, make it a popular choice for high-end signage, luggage exteriors, and jewelry boxes. Its corrosion-resistant and durable properties ensure that these products maintain their attractive appearance even after long-term use.

Frequently Asked Questions about Anodized Aluminium Mirror Sheet

How high is the reflectivity of anodized aluminum mirror sheets?

Depending on the specific processing techniques and surface quality, the reflectivity of anodized aluminum mirror sheets typically ranges from 80% to 90%. High-quality mirror aluminum sheets can achieve reflectivity close to 95%, making them widely used in lighting reflectors and decoration.

How long is the lifespan of anodized aluminum mirror sheets?

Anodized aluminum sheets have excellent corrosion and oxidation resistance, allowing them to maintain a long lifespan in both indoor and outdoor environments. Generally, anodized aluminum sheets can last 10 to 20 years or even longer, depending on the environmental conditions and maintenance.

Do anodized aluminum mirror sheets fade over time?

The color of anodized aluminum is formed through an electrochemical process, creating an oxide layer that does not peel off or fade like coatings or paints. As long as it is not exposed to extreme chemical substances like strong acids or bases, the color of anodized aluminum sheets can remain stable for a long time.

Can anodized aluminum mirror sheets be used outdoors?

Yes, anodized aluminum mirror sheets are highly weather-resistant and UV-resistant, making them suitable for outdoor applications such as building facade decoration. Their corrosion resistance allows them to maintain their original luster and texture for years in outdoor environments.

Are anodized aluminum mirror sheets prone to scratches?

The anodizing process enhances the hardness of the aluminum sheet and increases its scratch resistance, but the mirror surface is relatively smooth and should still be handled carefully to avoid scratches from hard objects. Protective measures such as applying a protective film can help prevent scratches during use.

Does the thickness of anodized aluminum mirror sheets affect their performance?

The thickness of anodized aluminum mirror sheets typically ranges from 0.2mm to 3mm. Thickness affects the sheet's hardness and impact resistance. Thicker sheets are generally more robust and are suitable for applications requiring strength and durability, such as architectural decoration, while thinner sheets are better suited for lightweight and aesthetic applications like appliance panels and electronic product housings.

Can anodized aluminum mirror sheets be customized in color?

Yes, anodized aluminum can be customized in various colors through the electrolyte and dyeing process, such as silver, gold, black, blue, etc. However, the durability and fade resistance of different colors may vary.

How to clean stains on the surface of anodized aluminum mirror sheets?

The smooth surface of anodized aluminum mirror sheets can be cleaned with a neutral detergent and a soft cloth. Avoid using acidic or alkaline cleaners to prevent damage to the oxide layer. For stubborn stains, professional aluminum cleaning agents are recommended.