Aluminum strip for flexible air ducts is usually made from high-quality, lightweight, corrosion-resistant aluminum alloy, most commonly 8011. The 8011 alloy offers excellent flexibility, durability, and resistance to environmental factors such as humidity and temperature fluctuations, making it ideal for HVAC (heating, ventilation, and air conditioning) applications.

Features of aluminum strip for flexible air ducts

- 1. Material: The most commonly used aluminum alloy for flexible air ducts is 8011, which has excellent formability, making it easy to shape into the desired configuration.

- 2. Thickness: The thickness of the aluminum strip for air ducts usually ranges from 0.08 mm to 0.2 mm, ensuring the material is lightweight yet strong enough to maintain its structural integrity.

- 3. Width: The width of these aluminum strips ranges from 50 mm to 1000 mm, depending on the specific requirements of the duct application.

- 4. Temper: Typically supplied in O temper (fully annealed), providing the aluminum strip with high flexibility, making it easy to mold into complex shapes.

- 5. Surface finish: The surface can be smooth or embossed, depending on the desired appearance and functional requirements. A smooth finish ensures minimal friction, while an embossed finish provides additional rigidity.

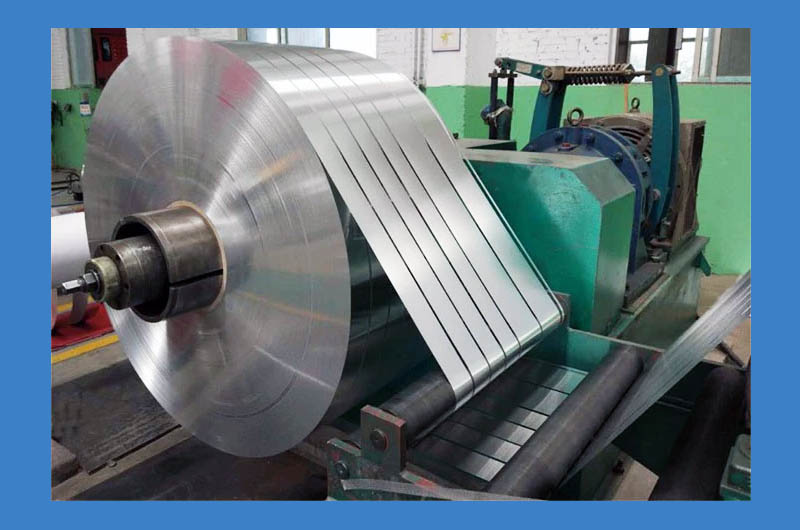

Aluminium strip for Air Duct Dimensions

| Product | Alloy | Temper | Thickness | Width | Diameter | Remark |

| aluminium air duct strip | 8011 | O | 0.08-0.13 mm | 60mm | 75, 150mm | Speciawidth can be made. according to your demands. |

Advantages of aluminum strip for flexible air ducts

- 1. Corrosion resistance: Aluminum naturally forms a protective oxide layer, giving it excellent corrosion resistance in humid environments, which is crucial for air duct applications.

- 2. Lightweight: The lightweight nature of aluminum reduces the overall load on building structures and makes installation easier.

- 3. High flexibility: Due to its excellent formability and ductility, the aluminum strip can be easily bent or coiled without breaking, which is essential for flexible air ducts.

- 4. Heat reflectivity: Aluminum strips have high reflectivity, helping to maintain effective thermal insulation within the duct system.

Surface Type of Aluminum air duct strip

- 1.Plain mill finish aluminum strip

- 2.DOS oil lubricated finish

- 3.Chromated finish

- 4. One side golden/white/red/blue/black, etc other colored, other side protective lacquered

- 5. both sides clear/transparent lacquered

Flexible air duct aluminum 8011 Chemical Composition

| Component | Content(%) |

| Aluminum (Al) | 97.5~99.1 |

| Iron (Fe) | 0.60~1.0 |

| Silicon (Si) | 0.50~0.90 |

| Copper (Cu) | 0~0.1 |

| Manganese (Mn) | 0~0.1 |

| Magnesium (Mg) | 0~0.1 |

| Zinc (Zn) | 0~0.1 |

| Chromium (Cr) | 0~0.1 |

| Titanium (Ti) | 0~0.05 |

| Residuals | 0~0.15 |

Applications of aluminum strip for flexible air ducts

- 1. HVAC systems: Aluminum strips are commonly used in the production of flexible ducts for HVAC systems, ensuring efficient airflow in heating, ventilation, and air conditioning systems. The flexibility of the material allows it to be installed in tight spaces where rigid ducts may not fit.

- 2. Ventilation systems: They are also used in exhaust and ventilation systems for residential and commercial buildings, where flexibility, corrosion resistance, and lightweight materials are essential.

- 3. Aluminum strips for flexible air ducts provide a durable, lightweight, and highly flexible solution for duct systems in HVAC and ventilation systems. They offer excellent corrosion resistance, ease of installation, and long-term performance in various environmental conditions.

The duct aluminum foil material produced by Haomei Aluminum features softness, elasticity, strong heat-sealing properties, and high-temperature resistance. It is widely used in range hoods, washing machines, dryer vents, and ventilation for bathrooms and restrooms.