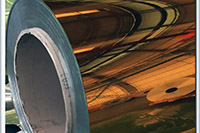

What is a Mirror Aluminum Sheet?

A mirror aluminum sheet is produced through specialized processes such as rolling and polishing, which give the aluminum sheet a reflective, mirror-like finish. The main goal is to achieve a high level of reflectivity on the aluminum surface, making it suitable for applications that require a smooth, reflective appearance.

Mirror aluminum sheets have a reflectivity rate of 86%-95% and offer a brighter, more aesthetically appealing surface compared to anodized mirror sheets, though the surface is more prone to scratching.

Characteristics of Mirror Aluminum Sheet Coil

- 1. Polishing Treatment: The surface of the mirror aluminum coil undergoes professional polishing treatment to display a mirror-reflective effect. Common polishing methods include mechanical polishing, chemical polishing, and electrolytic polishing. Through these methods, a very smooth reflective surface can be achieved.

- 2. High Reflectivity: The reflectivity of the mirror aluminum coil can reach over 86%, while high-reflectivity mirror aluminum coil can exceed 95%. This high reflectivity makes it particularly effective in lighting and reflective material applications, enhancing light efficiency and saving energy.

- 3. Surface Treatment: To enhance the durability of the aluminum coil and protect its surface, a transparent anti-scratch coating is usually applied on top of the mirror effect. This coating not only prevents scratches but also improves the weather resistance of the aluminum coil.

Specifications of Mirror Aluminum Sheet Coil

Mirror aluminum coils can be customized according to specific customer requirements, including single-sided or double-sided coating, and leveling to specific lengths. During production, the surface of the aluminum coil is treated to be smooth and scratch-free, with burr-free edges.

| Alloy | 1060, 1050, 1070, 1100, 3003, etc |

| Temper | H14, H16, H18, H22, H24, H26, O |

| Thickness | 0.28mm-1.60mm |

| Width | 30mm-1250mm |

| Sheet Standard Size |

1000*2000; 1200*2400; 1220*2440; other customized |

-

1050 Aluminum Mirror Sheet Coil

1050 aluminum mirror sheet coil is a type of mirror-finished aluminum coil made from 1050 aluminum alloy.

-

1060 Aluminum Mirror Sheet Coil

The 1060 Aluminum Mirror Sheet Coil refers to aluminum material with a 1060 alloy that has undergone special polishing and oxidation treatments, resulting in a high gloss finish and the ability to reflect light, similar to a mirror.

-

1070 Aluminum Mirror Sheet Coil

1070 aluminum mirror coil is a type of high-purity aluminum alloy coil with an aluminum content of up to 99.7%. Due to its high purity and smooth surface treatment, the 1070 aluminum mirror coil has an extremely high reflectivity, making it suitable for use as a light-reflecting material.

-

1085 Aluminum Mirror Sheet Coil

1085 aluminum mirror sheet is commonly used as a raw material for anodized mirror aluminum plates or coils. With a purity of up to 99.85%, 1085 aluminum boasts excellent reflectivity and a high degree of smoothness.

Polished Mirror Aluminum Sheet/coil Parameters

| MECHANICAL PROPERTIES | |||||||

| Type Ref. | Description of finishing | T.S (N/mm2) | Ys(N/mm2) | Elongation A50(%) | Minimum TotalReflectance( %) | Diffuse Reflectance( %) | MinimumBend Radil(T) |

| 1060 (H18) | Polished mirror | ≥160 | ≥85 | ≥1 | ≥87 | ≤12 | 1.0T |

| 1060(H16) | Polished mirror | 110-155 | ≥75 | ≥1 | ≥87 | ≤12 | 1.0T |

| 1060(H24) | Polished mirror | 95-135 | ≥70 | ≥2 | ≥87 | ≤12 | 0.5T |

Advantages of Haomei Mirror Aluminum Sheet Coil

- 1. Surface Quality: Free from oil stains, dents, impurities, scratches, stains, damage, corrosion, rolling marks, dirt streaks, and other defects.

- 2. Clear Image: Whether used for decorative elements, reflective surfaces, or industrial applications, the clarity of the image remains at the highest standard.

- 3. Durability: Highly durable, capable of withstanding extensive use over time without losing structural integrity or reflective quality.

- 4. High Reflectivity: Whether used in lighting fixtures, solar panels, or architectural design, high reflectivity ensures effective light reflection by the aluminum, enhancing energy efficiency and aesthetics.

Materials and Alloys of Mirror Aluminum Sheet Coil

1000 Series Mirror Aluminum Sheet Coil

The 1000 series aluminum sheet is the most commonly used alloy in mirror aluminum sheets, such as 1050, 1070, 1100, etc., with aluminum content of over 99.00%. Among these, 1060 aluminum coil is widely used due to its high reflectivity and excellent processing performance. Other alloys like 1050 and 1100 can also be used based on specific application needs.

- Alloy: 1050, 1060, 1070, 1100

- Temper: O/H12/H14/H16/H18/H24

Advantages

The production process is relatively simple, so the cost is also relatively low.

Applications

- Architectural Decoration: Due to its high reflectivity and smooth surface, it can be used in architectural decorative elements.

- Lighting Fixtures: Ideal for lighting applications where high reflectivity is crucial for enhancing brightness and efficiency.

- Solar Reflective Equipment: Used in solar panels and other reflective equipment to maximize energy capture and efficiency.

- Electronic Product Enclosures: Provides a polished and durable surface for electronic devices, enhancing both aesthetics and durability.

3000 Series Mirror Aluminum Sheet Coil

Compared to the 1000 series, the 3000 series offers higher strength and better bending performance. These alloys are particularly suitable for applications that require more durable and flexible materials.

- Typical Alloy: 3003, 3105

- Temper: O, H12, H14, H18, H19

- Reflectivity: The reflectivity of the 3000 series mirror aluminum sheet is 85%-90%, suitable for high-performance applications.

- 3003 Mirror Aluminum Sheet Coil is a common product in the aluminum-manganese alloy series. Due to the manganese alloy element, this product has excellent rust resistance.

- 3105 Mirror Aluminum Sheet, along with the 3003 series, ensures an aluminum purity of over 99.8%, with a mirror reflectivity of over 85% and transparency of over 94%.

Applications

- Architectural Components: Commonly used in building elements such as curtain walls, offering durability and a stylish appearance.

- Automotive Decoration: These alloys are often used in automotive parts due to their strength and corrosion resistance, offering both functionality and a modern appearance.

Classification of Mirror Aluminum Sheet Coil

Mirror aluminum sheet coils can be classified based on surface treatment, such as embossed mirror aluminum sheet coil, anodized mirror aluminum sheet, color-coated mirror aluminum sheet, etc.

Embossed Aluminum Mirror Sheet/Coil

Embossed mirror aluminum sheet coil is aluminum sheet coil that has undergone embossing treatment, giving it a surface with patterns like orange peel, spherical, diamond, and pebble patterns. Embossing not only increases the surface area of the aluminum sheet but also effectively enhances its heat dissipation performance. Additionally, embossing can increase the strength of the aluminum mirror sheet.

- Orange Peel Embossed Aluminum Mirror Sheet: The surface presents a texture similar to orange peel, offering good scratch resistance and decorative effect.

- Spherical Pattern Embossed Aluminum Mirror Sheet: The surface shows spherical patterns that can effectively disperse light and enhance decoration.

- Diamond Pattern Embossed Aluminum Mirror Sheet: The surface features diamond-shaped patterns, adding visual layers and uniqueness.

- Pebble Embossed Aluminum Mirror Plate: The surface resembles pebbles, providing both aesthetics and anti-slip effect.

- 5-Bar Embossed Aluminum Mirror Plate: The surface has 5 regular lines, commonly used in building decoration and flooring materials.

Anodized Aluminum Mirror Sheet

Anodized mirror aluminum sheet is aluminum sheet that has undergone anodizing treatment, forming a hard oxide film on the surface of the aluminum sheet, increasing its corrosion resistance and wear resistance. The mirror effect of anodized aluminum sheet can last for a long time, making it suitable for decorative applications requiring high durability.

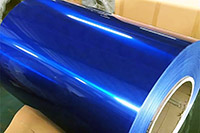

Color-Coated Aluminum Mirror Sheet

Color-coated mirror aluminum sheet is aluminum sheet coated with colored paint. The color coating not only provides a variety of color choices but also enhances the weather resistance and corrosion resistance of the aluminum sheet. It is commonly used in building facades, interior decoration, and other fields.

Mirror ACP Aluminum Sheet

Mirror aluminum composite panel (ACP) consists of multiple layers of material, with the top and bottom layers being color-coated mirror aluminum alloy sheets, and the core being non-toxic low-density polyethylene (PE). The front side is covered with a protective film. For outdoor applications, the front surface of the ACP can be coated with a fluorocarbon resin (PVDF) coating to ensure that the paint does not fade for 15 years. For indoor applications, the front surface can be coated with a PE coating.

High Reflective Mirror Aluminum

High reflective mirror aluminum sheet has extremely high light reflectivity and is commonly used in areas requiring high light reflection, such as lighting equipment and reflectors.

Mirror Aluminum Circle

Mirror aluminum circle is usually used to make various round aluminum products, such as decorative panels and signs, offering good reflective effects and visual aesthetics.

Applications of Mirror Aluminum Sheet Coil

Mirror aluminum coil is processed through methods such as rolling and polishing to achieve a mirror effect on its surface, making it widely used in various decorative and functional fields.

1. Indoor Decoration

Mirror aluminum coil is used in indoor decoration to significantly enhance the brightness and aesthetics of a space. It is commonly used for wall coverings, ceilings, grilles, and fluorescent lamp diffusers.

- Lighting fixtures and lampshades: Mirror aluminum coil is used in lighting fixtures and lampshades to improve light efficiency, protect the light source, and enhance the visual appeal of the lighting.

- Aluminum ceiling tiles and ceilings: Suitable for aluminum ceiling tiles and other indoor decorative materials, providing a bright decorative effect.

2. Outdoor Applications

- Building decoration: Used for exterior building decoration, including wall coverings, exterior walls, roofs, and canopies. Mirror aluminum coil reflects light, giving the building facade a modern look and visual impact.

- Elevator decoration: Mirror aluminum coil is commonly used in elevator interiors to enhance visual effects and durability.

- Tunnels and column covers: Used for decorating tunnels and column covers, enhancing visual effects and improving weather resistance.

3. Advertising and Marketing Applications

- Signs and labels: Enhances visibility and attractiveness of signs, widely used in advertising and marketing.

- Display platforms: Used for decorating display platforms, adding gloss and visual effect to the showcased products.

- Store signs: Mirror aluminum coil is used in store signs and storefront decorations to enhance brand image and attract customers.

4. Other Applications

- Home appliance panels: Mirror aluminum coil is often used for decorating panels of home appliances such as refrigerators and washing machines, enhancing the product's aesthetics.

- Automotive decoration: Used in automotive exterior and interior decoration to enhance the vehicle's visual effects.

- Electronic product casings: Applied to electronic product casings, increasing gloss and aesthetics.

- Luggage and nameplates: Used for decorating luggage, nameplates, and other products, enhancing durability and visual appeal.

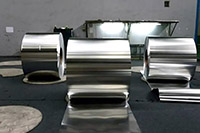

Mirror Aluminum Sheet Coil Production

In the production process of mirror aluminum sheet coil, the aluminum coil surface undergoes fine polishing and treatment to ensure its reflective effect and smoothness. A protective film is usually applied to prevent surface damage during transportation and handling.

1. Aluminum Coil Preparation

- Aluminum alloy selection: First, choose aluminum alloy raw materials suitable for mirror processing, commonly used are series 1050, 1060, and 1100. The selection of aluminum alloy directly affects the final product's quality and performance.

- Aluminum coil rolling: The aluminum alloy raw material undergoes preliminary hot rolling and cold rolling to form the basic shape of the aluminum coil. The rolling at this stage determines the thickness and basic surface quality of the aluminum coil.

2. Fine Polishing Process

- Surface grinding: The aluminum coil surface is subjected to multi-stage grinding to remove rough textures and surface defects generated during preliminary rolling. High-precision sandpaper or grinding machines are typically used for grinding to ensure a smooth surface.

- Polishing: The ground aluminum coil surface is finely polished. The polishing process includes using abrasive paste and polishing machines to achieve a high-gloss finish, creating a mirror effect. This process requires precise control to ensure uniform and smooth reflective effects.

3. Surface Treatment

- Cleaning: The polished aluminum coil undergoes thorough cleaning to remove residual abrasives and contaminants, ensuring a flawless surface.

- Protective film application: To prevent surface damage during transportation and handling, a protective film is usually applied to the aluminum coil surface. This protective film effectively prevents scratches, dirt, and other external impacts while maintaining the mirror-like gloss of the aluminum coil.

4. Inspection and Packaging

- Quality inspection: After production, each roll of mirror aluminum coil undergoes strict quality inspection. The inspection includes surface smoothness, reflective effect, thickness uniformity, and other factors to ensure that the product meets the specifications.

- Packaging: The inspected aluminum coil is carefully packaged. Packaging materials usually include protective paper, plastic film, and wooden pallets to ensure safe transportation. Product information and precautions are also marked on the packaging to ensure correct handling and use.

5. Transportation and Delivery

- Transportation: During transportation, mirror aluminum coils need to avoid severe vibration and impact to prevent damage to the protective film or scratches on the aluminum coil surface. Transport vehicles are typically equipped with appropriate protective measures to ensure the safe arrival of the aluminum coil at its destination.

- Delivery: Upon arrival at the customer's location, the aluminum coil undergoes a final inspection to ensure no issues occurred during transportation. Qualified products are delivered according to the customer's requirements, ready for use.

Mirror aluminum sheet coil, with its excellent reflective properties, superior surface treatment, and wide range of applications, is an important choice for modern decorative and functional materials.

Frequently Asked Questions About Mirror Aluminum Sheet Coil

1. What should I do if there are scratches or dirt on the surface of the mirror aluminum coil?

Cause: The surface of the mirror aluminum coil is relatively sensitive and prone to scratches or dirt, especially during transportation and handling.

Solution: You can gently wipe the surface with a soft cleaning cloth and a neutral cleaner, avoiding the use of rough tools or chemicals to prevent further damage to the mirror effect. If the scratches are deep, professional repair services may be needed.

2. How should I properly store mirror aluminum coils to prevent surface damage?

Cause: Improper storage may cause scratches or discoloration on the aluminum coil surface.

Solution: Store the mirror aluminum coil in a dry, clean environment, avoiding direct contact with the ground or walls. Using protective films and packaging materials can effectively reduce external impacts. Additionally, the storage area should maintain a constant temperature to avoid extreme temperature changes.

3. Will the reflective effect of the mirror aluminum coil change over time?

Cause: The reflective effect of the mirror aluminum coil may be affected by oxidation, contamination, or wear.

Solution: Regular cleaning and maintenance of the aluminum coil surface can preserve its reflective effect. Using specialized aluminum protectants can slow down oxidation and wear.

4. What happens to the mirror aluminum coil in a high-temperature environment?

Cause: High temperatures may cause discoloration or deformation of the aluminum coil surface.

Solution: Avoid exposing mirror aluminum coils to high-temperature environments. For applications requiring high-temperature resistance, choose aluminum alloys or surface treatment materials with high-temperature resistance.