1350 aluminum foil strips are widely used in transformer windings, especially in oil-immersed and dry-type transformers. Their high conductivity ensures high efficiency and stability of the transformer.

1350 aluminum alloy has an aluminum content of over 99.5%, and is known for its high purity and good conductivity.

The conductivity of 1350 aluminum alloy exceeds 62.0% IACS, making it suitable for electrical equipment that requires high conductivity. Additionally, its good formability allows it to be easily processed into various shapes to meet different design requirements.

Transformer Aluminum Foil Strips 1350 Types

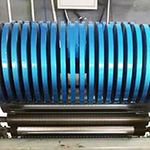

Bare Aluminum Foil Strips 1350 for Transformers Winding

- Application: Primarily used as winding material for oil-immersed transformers.

- Characteristics: The bare foil has no additional coating and is used directly as the conductive part, suitable for long-term use in oil-immersed environments.

Coated Aluminum Foil Strips 1350 for Transformers Winding

- Application: Primarily used as interlayer insulation material.

- Characteristics: The surface is coated with an insulating layer, improving interlayer insulation performance and preventing short circuits and electrical interference.

Transformer Aluminum Foil Strips 1350 Specifications

| Product name | Aluminium Foil strip for transformer winding |

| Grades | 1050, 1350, 1060, 1070 |

| Temper | O |

| Specification |

Thickness:0.2-3.5mm Width:20-1400mm |

| Quantity tolerance | ±10% |

| ID | 152.4, 200, 305, 405 and 505mm |

| Surface treatment | Mill finish |

| Application | Transformer winding |

| Packaging | Wooden Pallet |

Advantages of 1350 Aluminum Foil Strips for Transformers

1. High Conductivity

Due to its high aluminum content and good conductivity, 1350 aluminum foil effectively transmits current, enhancing the efficiency of transformers.

2. Excellent Formability

1350 aluminum foil can be processed into various thicknesses and shapes, meeting the diverse requirements of transformer design.

3. Good Corrosion Resistance

The corrosion resistance of the aluminum alloy ensures long-term use in harsh environments.

4. Cost-Effectiveness

Compared to copper materials, aluminum alloys are more cost-effective, providing an economical solution for transformer manufacturing.

With its high purity, excellent conductivity, good formability, and cost-effectiveness, 1350 aluminum alloy is an ideal choice for transformer winding materials. Its application in both oil-immersed and dry-type transformers, in the form of bare or coated foil, meets various electrical insulation and conductivity needs, ensuring stable operation and long-term reliability of the transformer.

Characteristics of 1350 O Aluminum Foil for Transformer Windings

- 1. Excellent Mechanical Properties: 1350 aluminum foil exhibits outstanding ductility and tensile strength, allowing it to be wound into tight and stable coils. This makes it perform exceptionally well in transformer winding applications, capable of withstanding various stresses during processing.

- 2. Good Plasticity and Processing Performance: The foil has good plasticity with uniform thickness and does not produce burrs during stamping, which enhances processing precision and surface quality. This is especially important for winding materials that require precise dimensions and smooth surfaces.

- 3. Superior Electrical and Thermal Conductivity: 1350 aluminum foil offers excellent electrical and thermal conductivity, ensuring efficient current and heat transfer in transformers, reducing energy loss, and improving overall performance.

- 4. Corrosion Resistance and Weldability: The foil's superior corrosion resistance allows it to withstand corrosive factors in various environments, extending the transformer’s service life. Additionally, its good weldability makes it more convenient during manufacturing.

- 5. High-Quality Surface Finish: The 1350 aluminum foil has a smooth surface with low pinhole density, which enhances the insulation performance and appearance of transformer windings. The smooth surface reduces potential electrical fault points, improving the reliability of the windings.

- 6. High-Temperature Resistance: The foil can endure high temperatures up to 130°C, adapting to the thermal challenges that transformers may face during prolonged operation. This characteristic ensures its stability and safety under high-temperature conditions.

1070 O Aluminum Strips Chemical Composition

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.7 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

Haomei Other Alloy Transformer Aluminium Strips

-

1050 Transformer Aluminium Strips

1050 aluminum strip has a conductivity better than 60% IACS. It is widely used in transformer windings. Its main applications include windings of dry and oil-immersed transformers.

-

1060 Transformer Aluminium Strips

Annealed or O-state 1060 aluminum strip has higher flexibility and ductility, and its conductivity is better than 61.5% IACS.

-

1070 Transformer Aluminium Strips

1070 aluminum strip has a conductivity of more than 62.7% IACS, and its thickness is generally 0.1mm to 3.5mm, which can adapt to the design requirements of different transformer windings and provide flexible options.