1060 aluminum strip is a high-precision aluminum strip commonly used in transformer manufacturing due to its superior electrical conductivity, corrosion resistance, good formability, and weldability. It is widely used in the production of transformers, especially in areas with stringent electrical and mechanical performance requirements.

The 1060 aluminum strip in the annealed state, or O-temper, has higher flexibility and ductility, which makes it easier to form and process in transformer windings.

Characteristics of 1060 O Transformer Winding Aluminum Strip

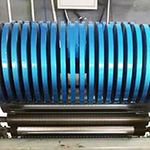

The 1060(O) aluminum strip is primarily used for high and low voltage windings of dry-type transformers. It has high electrical conductivity, a soft texture, a smooth surface, and no burrs, making it an ideal material for producing dry-type transformers and a key raw material for manufacturing transformer windings.

- 1. Excellent Conductivity: The electrical conductivity of 1060 aluminum strip is better than 61.5% IACS (International Annealed Copper Standard), which allows it to effectively conduct current and reduce energy loss in transformer windings.

- 2. Good Formability: The 1060 aluminum strip demonstrates excellent formability during processing, enabling precise cutting and forming to meet various transformer design requirements.

- 3. High Corrosion Resistance: This aluminum strip has excellent resistance to most chemicals and environmental factors, ensuring the stability and reliability of transformers during long-term use.

- 4. Good Weldability: The 1060 aluminum strip has good weldability and can be firmly connected with other materials using various welding methods, meeting the stringent connection quality requirements in transformer manufacturing.

Specifications of 1060 Transformer Aluminum Strip

| Alloy grade | Temper | Thickness /mm | Inner diameter /mm | Outer diameter /mm | Width/mm |

| 1050, 1060, 1070, 1350 | O | 0.08-0.20 | 150, 300, 400 | 700-980 | 16.0-1500.0 |

| >0.20-1.50 | 150, 205, 300, 350, 400, 000 | ||||

| >1.50-3.00 | 300, 400, 500, 600 |

Advantages of Haomei 1060 O Transformer Aluminum Strip

- 1. Low Cost: The 1060 O-temper aluminum strip has good conductivity, which means that using 1060 O-temper aluminum strip can significantly reduce the cost of copper strips for the same electrical requirements, achieving material cost savings.

- 2. Excellent Elongation: The 1060 O-temper aluminum strip has a higher elongation rate, making it perform well in stretching and forming processes, better meeting the deformation requirements in transformer manufacturing.

- 3. Good Workability: The 1060 O-temper aluminum strip exhibits excellent workability under normal conditions, ensuring consistency and stability in the production process, which enhances the overall quality of the product.

- 4. Superior Oxidation Performance: The 1060 O-temper aluminum strip performs exceptionally well in oxidation treatment compared to other alloys, offering a better oxidation effect. This not only improves the product's appearance but also extends its lifespan and reduces maintenance frequency.

- 5. High Flatness: The 1060 O-temper aluminum strip produced by Haomei boasts extremely high flatness, with a flatness error of less than 1/1000. This high-precision flatness ensures the stability and consistency of the aluminum strip in subsequent processing and applications, improving the overall product quality.

1060 Aluminium Strip Chemical Composition

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.6 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.0200 | 0.0022 | 0.0039 |

Transformer Aluminum Strip 1060 Tolerance

| Major brand | A1060(O)/A1050(O) | ||||

| Thickness | 0.2-0.4 | 0.4-0.8 | 0.9-1.1 | 1.2-1.6 | 1.8-2.0 |

| Tolerance | ±0.01 | ±0.015 | ±0.02 | ±0.025 | ±0.03 |

| Width | <100 | 100-200 | 201-500 | 501-1250 | >1250 |

| Tolerance | ±0.1 | ±0.2 | ±0.2 | ±1 | ±2 |

Transformer Aluminum Strip 1060 Burr and Collapse

| The width of aluminum belt | Burr’s height | Collapsed side’s height |

| <0.2 | 0.01 | ≥0.05-0.1 |

| 0.2-1.0 | 0.015 | |

| 1.1-1.5 | 0.02 | |

| >1.6 | 0.03 |

Applications of 1060 Transformer Aluminum Strip

- 1. Transformer Windings: The 1060 aluminum strip is primarily used in the manufacturing of transformer windings. Its superior electrical conductivity and workability make it an ideal choice for winding material. The aluminum strip serves both as a conductor and mechanical support in the windings.

- 2. Conductor Material: In various conductor components of transformers, the 1060 aluminum strip provides stable electrical conductivity and durability, ensuring the safe operation of transformers under high loads and harsh environments.

- 3. Electrical Insulation: The high corrosion resistance and excellent weldability of the 1060 aluminum strip make it a suitable material for electrical insulation components, helping to protect the internal parts of the transformer from external environmental factors.

Haomei Other Alloy Transformer Aluminium Strips

-

1050 Transformer Aluminium Strips

1050 aluminum strip has a conductivity better than 60% IACS. It is widely used in transformer windings. Its main applications include windings of dry and oil-immersed transformers.

-

1070 Transformer Aluminium Strips

1070 aluminum strip has a conductivity of more than 62.7% IACS, and its thickness is generally 0.1mm to 3.5mm, which can adapt to the design requirements of different transformer windings and provide flexible options.

-

1350 Transformer Aluminium Strips

1350 aluminum foil strip has a conductivity better than 62% IACS. It is widely used in transformer windings, especially oil-immersed and dry transformers. Its high conductivity ensures the high efficiency and stability of the transformer.